Domestic Preparation of Titanium-Tungsten Powder as Denitrification Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 08 February 2019 22:51

Nitrogen oxide is a serious air pollutant, which can cause environmental problems such as acid rain and photochemistry smog. It can also cause direct harm to human respiratory system. To win the Blue Sky Defense War, the important task is to effectively control the emission of NOx.

NOx emission sources mainly include coal-fired power plants, industrial enterprises and motor vehicles, of which the NOx emission from thermal power boilers accounts for more than one third of the total emissions. In order to strictly control the emission of NOx and effectively protect the environment, the Ministry of Environmental Protection promulgated the Technical Policy for the Prevention and Control of Nitrogen Oxides in Thermal Power Plants in early 2010, and began to implement the new Standard for the Emission of Atmospheric Pollutants in Thermal Power Plants in January 2012. The implementation of this standard will promote the rapid development of denitrification industry and put forward higher requirements for denitrification catalysts.

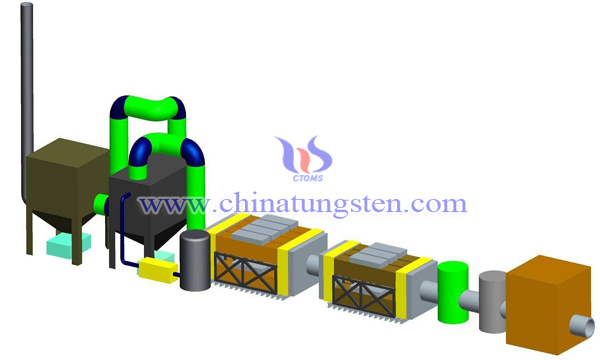

In order to meet the need of removing nitrogen oxides from industrial flue gas and break through technical barriers, Chinese scholars have been working on how to localize titanium-tungsten powder for catalysts, and have made progress. Recently, researchers have proposed a production scheme of domestically produced titanium-tungsten powder, which can be used for the preparation of flue gas denitrification catalysts, including the following steps:

(1)Preparation of metatitanic acid: Titanium oxysulfate solution and dispersant I were added into the thermostatic reactor respectively, and the temperature in the thermostatic reactor was controlled to be 55-70 ℃. Carbonate solution was added to the thermostatic reactor under stirring conditions, and the pH value of the mixed solution in the thermostatic reactor was adjusted to 2.0-2.5. After stirring for 1-2 hours, the mixed solution in the thermostatic reactor was filtered to obtain solid substance. Metatitanic acid particles were obtained by washing and drying solid materials.

(2)Preparing composite particles: After crushing the metatitanic acid particles prepared in step 1, dissolving them in the second reactor with tungsten solution, adding Tween 80 to the tungsten solution, stirring them for 4-6 hours at 50-60 ℃, then raising the temperature in the second reactor to 80-90 ℃, and steaming the water in the second reactor to obtain composite particles.

(3)Synthetic treatment: Ti-W powder which can be used for denitrification catalyst can be obtained by drying composite particles at 80-120 ℃ for 6-8 h and calcining them at 500-600 ℃ for 3-5 H.

It has been determined that the flue gas denitrification catalyst prepared with domestic titanium-tungsten powder has the characteristics of high denitrification efficiency and reliable production process, which is helpful to break through the technical barriers of foreign countries, thus greatly lowering the price of imported tungsten-titanium powder, and is of great significance to China's environmental protection construction.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com