Mesoporous Tungsten Carbide Synthesis

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 September 2018 22:40

Because the surface electron layer of tungsten carbide (WC) is similar to platinum (Pt), it has a Pt-like catalytic activity in some reactions. In addition to the field of cemented carbide, the application of tungsten carbide as a non-noble metal catalytic material with excellent performance has attracted much attention.

Since the 1960s, it has been reported that it has good catalytic activity for cyclohexane dehydrogenation and ethylbenzene dehydrogenation to styrene. Tungsten carbide not only has the potential to replace platinum and other precious metal catalysts, but also has strong acid resistance and good thermal stability, which makes it possible to use tungsten carbide as a high-performance catalyst in future fuel cells.

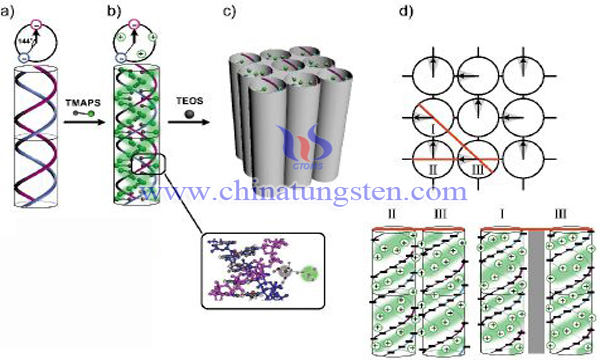

With the development of nanotechnology, particle refinement has become a major direction to improve the performance of catalysts, but the cost of product and catalyst separation due to particle refinement has been increasing. Preparation of mesoporous materials is an effective way to improve the performance of catalysts. The researchers used mesoporous tungstate to produce mesoporous tungsten carbide.

(1)Ammonium metatungstate was added to deionized water at room temperature and dispersed by ultrasonic wave for 5-30 minutes. The solution of ammonium metatungstate with mass concentration of 30-70% was obtained.

(2)Ammonium metatungstate solution prepared by step (1) was added to anhydrous ethanol at the speed of 1-5 mu l/drop and the interval of 2-8 s per drop (i.e. 2-8 s between adjacent two drops) under the action of ultrasonic wave. The precipitation was produced after instantaneous granulation and dispersed by ultrasonic wave, and then the ammonium metatungstate particles were obtained by filtering and vacuum drying. The ratio of total volume of ammonium tungstate solution to the volume of absolute ethanol is 1: 5~50 during the addition process.

(3)The obtained ammonium metatungstate particles are carbonized in CO/H2 atmosphere. The process is that the ammonium metatungstate particles are placed in a tubular reactor and heated to 700-900 ℃ for 2-8 hours in accordance with a 2-10 ℃/min program. The mesoporous hollow spherical tungsten carbide is prepared after cooling.

As the most important precursor of tungsten carbide, ammonium metatungstate has been widely used as tungsten source because of its advantages of non-pollution and convenient use. The redesign of ammonium metatungstate can realize the doping of precursors, control the structure and composition of precursors, and effectively control the hard agglomeration of particles in the carbonization process. In carbonization, gas-solid reaction is widely accepted because of its rapid carbonization and uniform distribution. In carbonization process, the decomposition and volatile components in the precursor after granulation are decomposed into gases at high temperatures to form pores, which make tungsten carbide particles nano-scale accumulation and obtain double-porous structure. The catalyst performance can be greatly improved. But the cost is effectively controlled.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com