Tungsten Oxide-Vanadium Pentoxide Nanowire Electrochromic Materials

- Details

- Category: Tungsten Information

- Published on Thursday, 09 August 2018 19:03

Electrochromism refers to the reversible change in light transmittance and/or reflectance associated with an electrochemical redox reaction after the material is applied with an appropriate voltage. Applications of electrochromic devices include: smart windows for cars and buildings, controllable light reflection or light transmissive display devices (for optical information and storage), controllable aircraft canopies, reusable price tags, spacecraft Thermal control and more.

Among numerous inorganic electrochromic materials, transition metal oxides have attracted a wide range of interest, including cathode coloring materials (tungsten oxide, molybdenum oxide, titanium oxide, vanadium oxide) and anode coloring materials (nickel oxide, cobalt oxide). Among them, vanadium pentoxide is both an anode coloring material and a cathode coloring material. However, vanadium pentoxide films also have some disadvantages in electrochromic devices, such as poor cycle stability, low conductivity and lithium ion diffusion coefficient, poor contrast, and low coloring efficiency. As the most promising inorganic electrochromic material, tungsten trioxide has unique color-changing properties compared with other transition metal oxides, such as low cost, easy synthesis, low energy consumption, high contrast, high coloring efficiency and Excellent cycle stability.

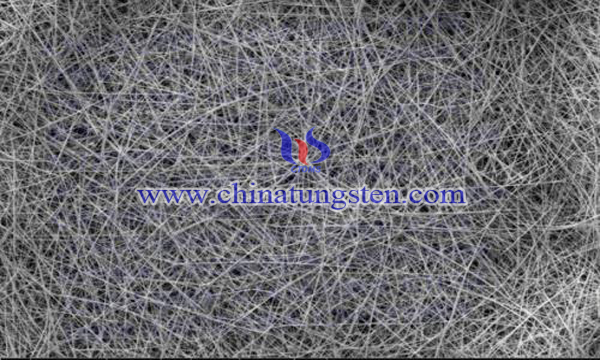

Therefore, the manufacture of tungsten oxide-vanadium pentoxide core-shell nanowire array electrochromic materials can combine the advantages of both: the specific steps are as follows:

1) The FTO conductive glass is sequentially ultrasonically cleaned in acetone, ethanol and deionized water, and after being cleaned, it is baked under an infrared lamp;

2) Prepare a peroxo-tungstic acid solution: dissolve the tungstic acid powder in a mixed solution of 30% hydrogen peroxide and deionized water, stirring the solution to clarification, and then diluting the solution with deionized water to a concentration of 0.05-0.1 Mol / L, the diluted solution is a peroxo-tungstic acid solution;

3) prepare a precursor solution: prepare a mixed solution of the peroxo-tungstic acid solution prepared in the step (2) with acetonitrile and deionized water, and then adjusting the pH of the mixed solution to 0.5-1 with hydrochloric acid to prepare a precursor solution;

4) The precursor solution prepared in the step 3) is added to the high pressure reaction kettle, the FTO conductive glass is vertically immersed and fixed in the precursor solution, and the high pressure reaction kettle is heated to 150-220 ° C for 6-12 hours; After the hydrothermal reaction is completed, the FTO conductive glass is taken out, the surface is rinsed with deionized water, and dried at room temperature to obtain a WO3 nanowire array film;

5) The FTO conductive glass containing the WO3 nanowire array film obtained in the step 4) is used as a working electrode, the platinum wire is used as a counter electrode, and the Ag/AgCl electrode is used as a reference electrode, and vanadium sulfate and sodium lauryl sulfate are used. And the sodium chloride is dissolved in a mixed solution of absolute ethanol and deionized water as an electrodeposition solution, and the working electrode is subjected to cyclic voltammetry deposition;

6) The product obtained in the step 5) is washed with ethanol, placed on a filter paper, and dried by an infrared lamp to obtain a dense and uniform yellow-green film on the FTO conductive glass, which is a tungsten trioxide-vanadium pentoxide nanowire. electrochromic material.

The color cathodes of tungsten trioxide and vanadium pentoxide are similar in color, and have a synergistic effect when the cathode is colored, which greatly improves the contrast of the electrochromic material, and the interface is effectively hybridized to complement each other.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com