The Market of Tungsten Carbide Dies

- Details

- Category: Tungsten Information

- Published on Friday, 06 July 2018 17:01

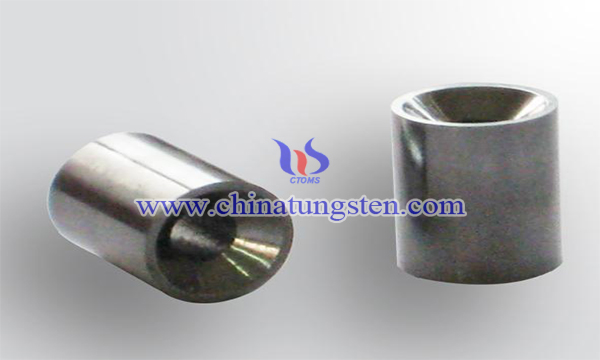

Mould is the basic technological equipment for industrial production. With the introduction of computer aided technology into the mould industry, the digital process of product design and manufacture has been promoted. The market status of the tungsten carbide mould has been promoted gradually, promoting the new innovation of the technology of the mould industry.

The development of large tonnage mechanization and automatic processing forming equipment, and the extensive application of hot forging die, hot extrusion die, hot pier die, die casting die and so on, put forward higher requirements for the strength, impact toughness, red hardness and wear resistance of tungsten carbide die. Because of the poor toughness of cemented carbide dies, it is easy to crack. Poor wear resistance of materials at high humidity leads to a significant reduction in service life of tungsten carbide dies. Therefore, it is more and more important and urgent to improve the strength and hardness of hot working die materials and prolong the service life of dies.

In order to improve the life of cemented carbide die, it is necessary to correctly design the structure of the cemented carbide die, make the tungsten carbide die parts accurately, rationally use the tungsten carbide die and the heat treatment process. At the same time, high quality cemented carbide die materials are selected according to the actual production needs, and a reasonable heat treatment process is selected to give full play to various properties of die materials and improve the service life of the tungsten carbide die. The quality of the mold material, the rational use and other factors are closely related to the accuracy of manufacturing, the rate of qualified products, the carrying capacity, the life and the cost of tungsten carbide dies.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com