Tungsten Carbide with Direct Reduction Carbonization Technology

- Details

- Category: Tungsten Information

- Published on Sunday, 22 April 2018 17:53

Superfine cemented carbide obtained by ultrafine tungsten carbide powder has high strength and high hardness. It is Widely used in the production of integrated circuit board micro drill, dot matrix printer print needle, precision mould, tool, woodworking tools, medical drill etc..

Direct reduction carbonization technology is an advanced technology, tungsten carbide powders were obtained by heating with a tungsten precursor powder and a certain proportion of carbon source in a non oxidizing atmosphere, and the reduction reaction was carried out at the same time with carbonization. The total carbon content of the direct reduction method is close to 6.13%, high quality tungsten carbide powder with low free carbon, the main processes are as follows:

1. The precursor powder is wet-milled in an alcohol solution for 12-30 hours and then dried for 5-30 hours, sieved, loaded into a graphite boat, and carbonized in a non-oxidizing atmosphere. The carbonization temperature is 1000~1400°C, the mass fraction of carbon black in precursor powder is 13.4 to 14.5%, and the allowance is violet tungsten with particle size less than 12μm. The carbonization product is obtained at one carbonization time for 1~3 hours.

2. The obtained one-time carbonization product is mixed for 2~3 hours by ball milling, the content of carbon was detected and the amount of carbon was adjusted to 6.10 ~ 6.30% , after ball milling for 3~6 hours, two-time carbonization in hydrogen atmosphere, two-time carbonization temperature is 1200~1300°C and carbonization time is 1~3 hours, then two-times carbonization products were obtained.

3. The obtained two-time carbonated products are milled for 4~6 hours, and the ultrafine tungsten carbide powders are obtained by sifting.

To get a better particle size distribution, we can add chromium oxide in precursor powder as crystal growth inhibitor, then ball milling. The optimum addition ratio of chromium oxide is 0.7% ~ 1% of precursor powder weight.

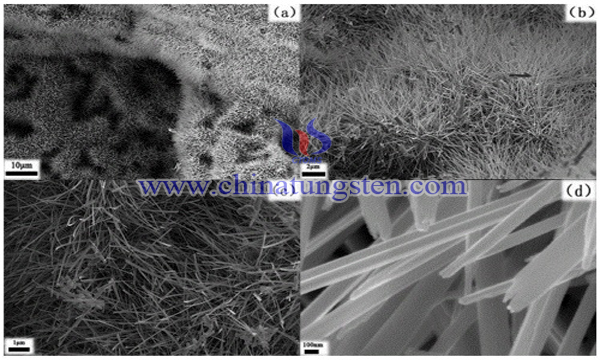

Tungsten carbide "direct reduction carbonization technology" is a simple process. Violet tungsten is more suitable for preparing fine particles. After long ball milling, the size of the violet tungsten is finer and the carbonization can be reduced directly under the appropriate conditions, which can make the carbon content of the product better controlled. Therefore, the particle size distribution of the ultrafine tungsten carbide powder produced is narrow, the dispersion and the uniformity are better, the total carbon content is closer to the chemical measurement carbon and the free carbon is lower.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com