Rare-Earth Yttrium Dispersion Strengthened Fine Tungsten Materials

- Details

- Category: Tungsten Information

- Published on Saturday, 21 April 2018 23:41

Tungsten has high melting point, high hardness, good high temperature strength, heat conduction, electrical conductivity, low coefficient of thermal expansion, low sputtering with plasma, no chemical reaction with H, low retention of H+, etc. It is a very important high-temperature structural material and functional material. It is widely used as material for plasma and divertor parts in nuclear fusion.

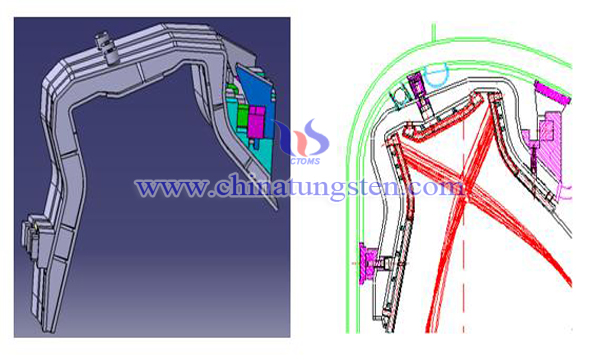

A high performance rare earth yttrium dispersion strengthened fine grain tungsten materials was prepared by non homogeneous precipitation spray drying calcining calcining heat reduction and conventional sintering technology. The density of the rare earth was close to all dense (more than 98.5%). The rare earth yttrium particles dispersed in the tungsten grain and tungsten grain boundary, and the microstructure was uniform and fine. The average grain size was 10 m. It has good mechanical properties at room temperature and high temperature, and high impact resistance to high heat load. The dispersion strengthened fine-grained tungsten material with W-0.1wt%Y2O3 as an example is taken as an example.

(1)According to the final mass fraction of rare earth oxides prepared, the soluble rare earth salts and tungstate salts, called 1.02g yttrium nitrate and 411.27g ammonium tungstate, are prepared by the mass ratio. The rare earth salt solution of 50g/L and the tungsten salt solution of 150g/L are prepared respectively.

(2)The ammonia water in the yttrium nitrate solution is slowly added to the concentration of 10wt%, adjusting pH to 7.2, and adding 0.2g PEG400 as a reactive dispersant. Under the action of ultrasonic vibration and electric mixer, the rare earth salt and alkali are reacted to form a uniformly suspended Y (OH) 3 colloid, and then the tungsten salt solution is added to the colloid of Y(OH)3. Slowly adding 10% by weight of oxalic acid, adjusting the pH to 6.5, and adding 2g of PEG400 as a reaction dispersant, the tungstate is formed into tungstic acid microparticles under ultrasonic vibration and stirring by an electric mixer. Taking Y(OH)3 colloidal particles as the core, precipitated around Y(OH)3 colloidal particles, and finally formed coprecipitation particles colloid.

(3)Then, the colloid was spray dried at 360 degrees Celsius, and the rotational speed of the spray was 20000 R / min, and the composite precursor powder of tungsten and yttrium oxide was obtained.

(4)The composite precursor powder was calcined at 350 ℃. and calcined for 2 hours. After being deagglomerated and sieved, the mixture was incubated at 780 ℃. Under H2 atmosphere for 4 hours to obtain ultrafine tungsten powder containing 0.1% by weight of Y2O3 .

(5)The superfine W composite powder containing 0.1wt%Y2O3 was moulded, and 2H was burned at 1950 centigrade after presintering, and the W-0.1wt%Y2O3 material was obtained. The density of the material is above 99.2%, the microstructure is fine and uniform, the grain size is below 10 um, and the sample surface does not crack under the impact of high heat flux density of 200MW/m2.

Compared with the high energy ball milling mechanical alloying, the ultrafine tungsten composite powder containing rare earth yttrium containing rare earth yttrium prepared by the non homogeneous precipitation spray drying calcining hydrogen reduction method has greater sintering activity, better density, the grain size of the sintered body is 5~10 um, and the microstructure is more uniform, with more uniform structure, and excellent room temperature, high temperature toughness.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com