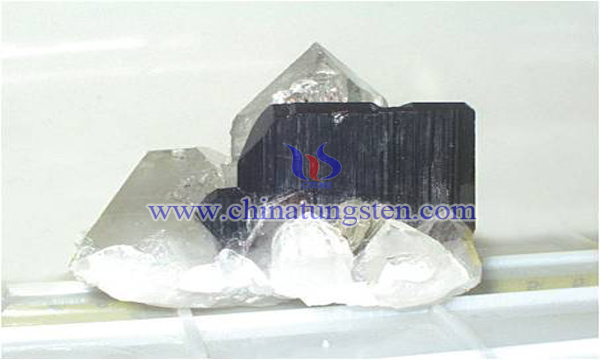

Tungsten Ore Fluorite Comprehensive Decomposition Method

- Details

- Category: Tungsten Information

- Published on Saturday, 21 April 2018 23:21

China is recognized as a fluorite resource country, producer, and exporter in the world. The reserves, extraction volume and export volume rank first in the world. Fluorite is the most important mineral in fluoride. It has unique physical and chemical properties, and has a wide range of uses. It plays a decisive role in industrial development. However, China's single-type fluorite deposits have small reserves, and the rich tungsten ore with a CaF2 grade of more than 65% is less than 23% of China's fluorite reserves. Most of the fluorite resources are associated minerals and are mainly associated with scheelite.

Taking the associated ore of polymetallic fluorite in Shizhu garden in Hunan Province as an example, its tungsten reserves are 700 thousand tons, the world is the first in the world; the associated fluorite reserves are 75 million 640 thousand tons. It is the largest associated fluorite in the world. With the development of the economy, the demand for fluorine is growing, and the high quality fluorite is thinner and less. Therefore, the comprehensive utilization of associated fluorite ores is increasingly on the agenda.

Due to the similar floatability of calcium minerals such as scheelite and fluorite ore, in the process of floatation of scheelite, we have to add inhibitors to the strong inhibition of calcium containing minerals such as fluorite. On the one hand, such inhibition also has a negative effect on the recovery of scheelite. On the other hand, the floatability of the fluorite is worse and the subsequent recovery is seriously affected, and one hundred thousand tons of fluorite flow to the tailings reservoir each year, causing a large amount of waste of resources. For this reason, the researchers changed the beneficiation idea of single flotation Scheelite Concentrate and fluorite concentrate, and redesigned the comprehensive decomposition plan of mixed concentrate.

Sulfuric acid and phosphoric acid are used to decompose 1kg fluorite concentrate containing tungsten (including CaF295.6%, WO3 2.7%). The molar ratio of the concentration of 98% sulfuric acid to the mineral content is 1.2, the molar ratio of the WO3 content of phosphoric acid to the mineral is 1, the calcination temperature is 250, and the calcination time is 6h. The HF gas produced during the calcination process is used to prepare hydrofluoric acid, and the decomposition rate of CaF2 is 96.2%. The fluorogypsum obtained after the process of roasting junction is leached by H3PO4 with a concentration of 100g/L. The ratio of liquid to solid is 5:1, the leaching temperature is 80, the leaching rate of tungsten is 96.5%, and the slag containing WO3 is 0.056%. The filtrate obtained after the leaching process can be returned to a new round of leaching of tungsten containing fluorogypsum. The tungsten in leaching solution was adsorbed on primary amine anion exchange resin, and the adsorption rate was 98.5%.

The scheme uses sulphuric acid and phosphoric acid sintered tungsten fluorite minerals. The fluorite minerals are decomposed to HF gas to prepare hydrofluoric acid. At the same time, scheelite turns into soluble phosphotungstic acid to extract tungsten, which ensures the decomposition rate of fluorite and scheelite, the decomposition rate of fluorite reaches more than 95%, and the recovery of tungsten is over 90%. The content of WO3 in fluorogypsum is reduced to less than 0.1%.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com