Purification Scheme of Barium Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Monday, 05 February 2018 16:11

With the increasing consumption of tungsten resources, high-quality high-grade tungsten ore is also gradually reduced, black and white mixed tungsten ore and low-grade impurities such as high-grade refractory tungsten is gradually flowing to the market, tungsten smelting enterprises have brought many difficulties and pressures.

In order to reduce the production pressure, at present, all the production enterprises have certain requirements on the content of impurities in the tungsten ore when they purchase the tungsten. In particular, they have strict requirements on the content of barium. This is because barium tungsten ore is difficult to decompose at high temperature, and the higher the content of barium, the greater the influence on decomposition. It seriously affects the decomposition rate and reduces the recovery rate of metal. It is a difficult problem for the enterprises to use alkali digestion and dissolution.

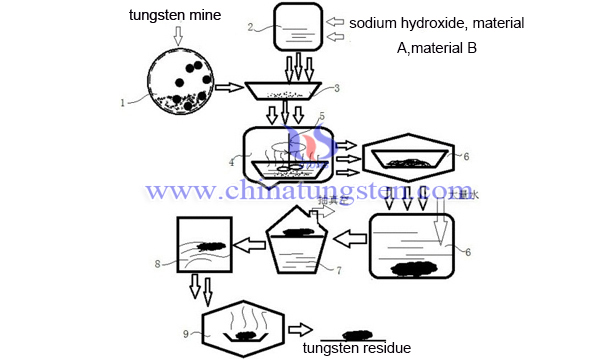

Some scholars have proposed a tungsten ore purification of barium dissolution method, which includes the following steps:

The tungsten ore containing barium was grinded with a ball mill to make the particle size less than 325 of the particle reach more than 95%, and the tungsten ore was placed in the porcelain crucible. In the dissolving container, we use tap water to dissolve sodium hydroxide, catalyst and barium tungsten ore decomposition promoter, and the solution is added to the porcelain crucible with tungsten ore in place before stirring. The material will be installed in the crucible furnace on the dry side boil while stirring, to prevent splashing; After drying, then transferred to the provisions of the muffle furnace temperature, reaction half an hour, with a lot of tap water dissolved into the container, for dissolution; The resulting solid-liquid mixture was stripped and suction-filtered through a vacuum suction filter. The resulting tungsten slag was washed twice and then burned in a muffle furnace.

The results show that the above method can decompose the barium-containing tungsten ore more than 95%, which effectively solves the problem of refractory high barium tungsten ore and significantly improves the decomposition rate of barium-containing tungsten ore.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com