Sintering Driving Force - Saturation Vapor Pressure Difference

- Details

- Category: Tungsten Information

- Published on Monday, 22 January 2018 22:16

For tungsten carbide, the surface tension causes the macroscopic flow of the material to the pores at the neck of the sinter. And the material migration of atomic diffusion caused by the difference of the degree gradient caused by the concentration gradient of the vacancy. There may also be a matter of evaporation from the surface of a particle to space. It also has a direct effect on the densification of the sintering and the change of the pore.

The sintering power can be studied from the angle of vaporization of the material. Namely, the difference between the saturated vapor pressure of the sintered dynamic surface and the saturated vapor pressure of the plane is expressed by the difference of the saturated vapor pressure, which can be calculated by the Gibbs Kelvin (Gibbs-Kelvin) equation.

ΔP=PγΩ/kTr(1)

Where: r-- radius of curvature of a surface.

P-- saturated vapor pressure of the plane.

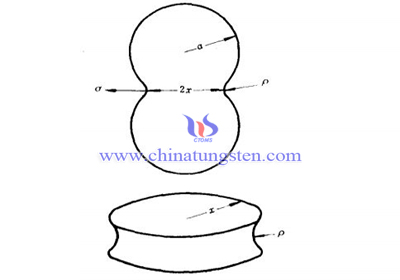

According to the two-ball model, radius of curvature r of surface for half a catty is

1/r=1/x-1/ρ(2)

Simultaneous (1), (2) and because P《 X, 1/r ≈ -1/ P

ΔP = -PγΩ/kTρ(3)

Similarly, for the spherical surface of tungsten carbide, the radius of curvature satisfies 1/r=2/α(α is radius of sphere).

ΔP =2PγΩ/kTα (4)

It is known from (3) that the vapor pressure of the sintered neck surface (concave surface) should be lower than the saturated vapor pressure of the plane P. A larger vapor pressure difference exists between the particle surface (convex surface) and the surface of the sintered neck, and the difference is the value of (4) - (3), which will lead to the migration of material to the sintering neck. Therefore, in the sintering system, the vapor pressure difference everywhere is the driving force of the transfer of the sintering through the material.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com