Effect of Water Content on the Apparent Density

- Details

- Category: Tungsten Information

- Published on Saturday, 30 December 2017 18:57

Tungsten carbide mixture composed of WC powder (or other refractory carbide powder), Co powder and forming by wet grinding and dry granulating process preparation. In these processes, the mixture contains a certain amount of moisture, which will follow the process into the mixing stage. The water content of mixture will have a certain impact on the apparent density, which can be controlled during the spray drying process.

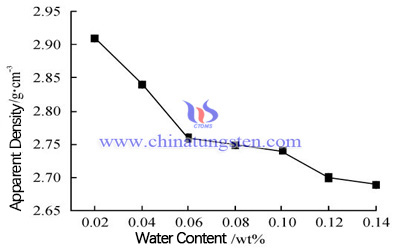

Effect of Water Content on the Bulk Density of the Mixture

It can be seen from the diagram that the water content has a great influence on the bulk density of the powder. With the increase of water content, the density of loose assembly decreases. The reason is that when the water content is large, the capillary force between the particles is increased, and the powder is easy to be reunion for two times.

When particles are stacked, the phenomenon of arch bridge is generated. Particle rearrangement is not easy to carry out, so that the void between particles cannot be effectively filled, resulting in loose bulk density of powder.

Change the Flow Velocity of Gas in Spray Drying

The water content of the mixture can be controlled and adjusted by the spray drying process. When the drying temperature, spray pressure and drying chamber capacity are fixed, the heating gas flow rate increases, and the time for heating gas to stay in the tower decreases, that is, the contact time between the material and the hot gas decreases.

As the material is not dried completely, the ball is not good, and the fine powder is more, the fine powder after drying is easy to be brought out of the tower by heating gas, so the actual yield of the mixture is obviously reduced.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com