Characteristics of High Velocity Compaction

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 December 2017 20:53

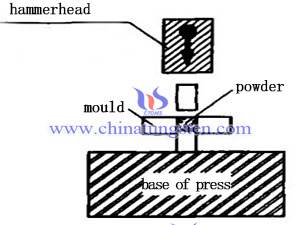

High velocity compaction (HVC) is an advanced forming technology put forward by Sweden in 2001. It has many characteristics, such as dynamic impact energy and traditional high speed and smoothness. It can be widely used for forming metal, ceramic and polymer materials.

At present, high velocity compaction technology has also begun the technical exploration of tungsten carbide powder metallurgy. The forming method has many characteristics, such as good performance of billet, low elastic after-effect and so on. The characteristics of this technology for tungsten carbide are as follows:

1, Good Performance of Pressed Compact

The HVC technology makes the parts with high density by using a strong shock wave. It can not only make the parts high densification, but also make the density homogenized. Compared with the traditional technology, the HVC technology can increase the density of the pressed compact by more than 0.3g/cm3. Other performance indicators have also been greatly improved.

2, Low After-Effect

Because the elastic aftereffect is related to the geometric shape of the billet and the powder material, the radial elastic after-effect of the blank formed by HVC technology is lower than that of the traditional press. Usually, the mixture powder has small elastic deformation in the compaction, and the elastic aftereffect is less than that of other kinds of powder.

3, High Efficiency

The pressing speed of HVC is 500~1000 times faster than that of traditional pressing, which is the same as that of the traditional pressing process. As a result, it can be used in mass production. HVC rapidly increases the density by continuous high frequency shocks. While repeated repression in the traditional suppression do little in the increase of density. This rapid multiple repression is practical in forming large parts and can produce super large parts with smaller equipment and lower cost.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com