High Velocity Compaction Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 December 2017 20:46

High velocity compaction technology belongs to dynamic pressing forming, which is a technology of forming powder with the speed that is obviously higher than the traditional technology. Its pressing speed is 2-30m/s, and the dynamic pressure is rapidly formed and densified by the propagation of shock wave or stress wave in the powder.

Compared with the traditional static rigid die pressing, it has many similarities with the common process in powder filling and parts demoulding. The pressing speed of high velocity compaction is 500~1000 times faster than that of the traditional pressing method, and it can also realize multiple impact repression during the time interval of 0.3 ~ 1s. The equipment, mould and densification mechanism are three important aspects of high velocity compaction technology.

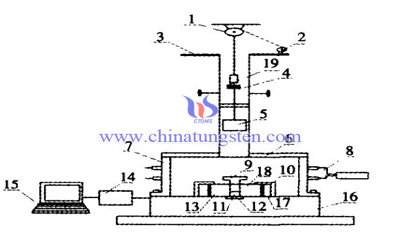

1, Equipment of High Velocity Compaction

At present, high-speed compaction can drive high speed through various ways, such as compressed air, explosive mixture, magnetic drive, mechanical spring and so on. Usually, the hydraulic power unit control the oil circuit system is adopted to achieve the high-speed drop and promotion of hammers, and achieve high speed impact suppression and high speed suppression in a short time interval.

2, Mould of High Velocity Compaction

Die life is still the key factor that affects the industrial application of high speed pressing technology. In the process of high velocity compaction, the energy of the upper die absorption cannot be ignored. When designing the mold, the quality of the punch can be reduced as much as possible and the length to diameter ratio need to be improved, thus improving the utilization of energy.

Presently, the density and performance of the high-speed compaction are higher than that of the conventional pressing. But in high velocity compaction condition, may cause between powder and die wall welding, the powder compacts are from the die off. Therefore, the successful development of the lubrication system is one of the key technologies for high speed suppression.

The design and material selection of the die are the key to the popularization and application of HVC technology. HVC technology is very similar to the die pressed by powder metallurgy, but dies must withstand severe shock waves. Therefore, it must be designed for shock resistance, and the die life is more than 100 thousand times. So the mold usually made of high toughness material.

3, Densification Mechanism

Some scholars in China put forward the "thermal softening shear densification mechanism". It is thought that particle bonding is a "notch" during prepressing process. When the preformed blank is under the suppression, the "gap" near the particle surface to form a high temperature shear zone and the rapid spread of the particles are prone to plastic deformation or local welding, so as to achieve a high degree of densification.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com