Tungsten Tube Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 18:31

Tungsten tube is also called wolfram tube, which is made with purity of 99.95%min. Meanwhile, its density can be higher to 18.2g/cm3 for sintering and 19.2g/cm3 after swaging. Tungsten tube is also with tungsten properties, high melting point, high boiling point, high temperature resistance, corrosion resistance and low thermal expansion. So it can be used as pipe in melting other metals. We specialize in supplying seamless tungsten tube with a variety of dimensions including round, rectangular, square, and oval in numerous standard diameters from 0.02 to 6.0 inches and wall thicknesses from 0.003 to 0.500 inches. Tungsten tube can be further processed to produce rings, washers, sleeves and sheaths. Custom configurations are also available. Materials include most metals including the rare earth metals and other advanced materials. Tungsten tubes can also be produced from custom materials and alloys for commercial and research applications and for new proprietary technologies. Other available shapes include bar and plate form, as well as custom machined shapes and through other processes such as nanoparticles and in form of solutions and organometallics. We also produce tungsten as rod, pellets, powder, pieces, granules, wire and in compound forms, such as oxide. Other shapes are available by request.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

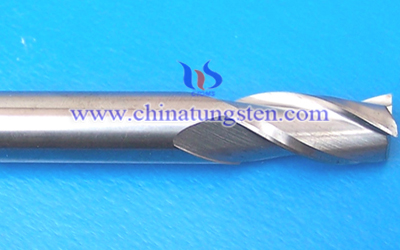

Tungsten Carbide High Speed End Mills Structural Features

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 18:12

Tungsten carbide cutting tools structure is an important factor in the decision to performance of tungsten carbide cutting tools.Tool manufacturers at home and abroad attached great importance to tungsten carbide tools structure research and development.

Tungsten carbide high speed end mills structural features have two main aspects. On the one hand, tungsten carbide high speed end mills are mainly whole and tipped categories. Due to centrifugal force and high-speed machining shake, structural safety and balance of tungsten carbide high speed end mills are essential. Tungsten carbide high speed end mills system must have good balance and security.Tungsten carbide high speed end mills structural features on the other hand lies in that tipped categories usually use tool machine folder structure, Centrifugal force which will cause carbide blade and blade intensify structural damage and broken blade or get rid of, so the knife body and clamping mechanism must have high strength and fracture toughness and rigidity to ensure safe and reliable.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Powder Extrusion Molding Strategy

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 18:00

Tungsten Carbide Rod Powder Extrusion Molding Strategy

Although tungsten carbide rod powder extrusion molding has improved a lot in recent years, there are also many problems like immaturity in the research of knowledge and technology. Especially the research of rheology extrusion has a great distance with other countries. The only thing we can do is to keep doing research in order to catch up with or even surpass advanced world levels. The following are some strategy for the existing problems:

1.Actively develop the technical research in rheology extrusion. Organize the research group; mirror other rheology method like industrial rheology and basic rheology to study the extrudate performance and basic rheological behavior so that we can apply rheology parameter in the research of extrusion molding.

2.Vigorously develop the extrusion binder. In the present we have no resources from other countries and there is no access to get information from the report. So we can only do the research by ourselves and make cooperation with chemical engineering, produce practical binder which can fit in various types of tungsten carbide powder.

3.Develop the research in the synchronization of tungsten carbide rod powder extrusion molding and equipment. Figure out the influence of rheology extrusion under different feedstock on the density of the tungsten carbide rod and extrusion method.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Powder Metallurgy History

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:58

Tungsten Carbide Rod Powder Metallurgy History

The history of tungsten carbide rod powder metallurgy and the art of metal and ceramic sintering are intimately related to each other. Sintering involves the production of a hard solid metal or ceramic piece from a starting powder. "While a crude form of iron powder metallurgy existed in Egypt as early as 3000 B.C, the smiths of India produced the famous "Iron pillar of Delhi", weighing about 6.5 tons, and other objects even larger as early as 300 A.D, and the ancient Incas made jewelry and other artifacts from precious metal powders, mass manufacturing of P/M products did not begin until the mid- or late- 19th century.

The invention of tungsten filament lamp impels the development of powder metallurgy. In 1932, tungsten carbide rod powder metallurgy marks a great improvement in powder metallurgy. Tungsten carbide rod powder metallurgy overcomes the casting problems of the refractor metal.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Molding Process

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:55

Tungsten Carbide Rod Molding Process

Tungsten carbide rod molding process can be divided into two methods which are horizontal direction and vertical direction.

Horizontal direction:

Firstly, shape the two punches of the mold into a round-rod shape and press out powder between them. Under this process, the length of rods would be easily restricted by the specifications of the mold and pressing machines. Due to the uneven pressure from both punches, there can be gaps formed in the blank voids, and they are difficult to close. There are some possibilities that the cobalt contents is increasing and thus creates the so-called cracking which can not be fixed.

Vertical direction:

Similar to the horizontal repression process, the specifications and length of the rods are also being restricted by the specifications of the mold and pressing machines and cannot be easily extruded out in the vertical direction.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Isostatic Pressing

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:48

Tungsten Carbide Rod Isostatic Pressing

Tungsten carbide rod isostatic pressing is a mass-conserving shaping process. Fine metal particles are placed into a flexible mould and then high gas or fluid pressure is applied to the mould. The resulting article is then sintered in a furnace which increases the strength of the part by bonding the metal particles. This manufacturing process can be used to make many different shapes. Tungsten carbide rod isostatic pressing can be divided into hot isostatic pressing and cold isostatic pressing.

Hot isostatic pressing (HIP) compresses and sinters the part simultaneously by applying heat ranging from 900 °F (480 °C) to 2250 °F (1230 °C). Argon gas is the most common gas used in HIP because it is an inert gas, thus prevents chemical reactions during the operation.

Cold isostatic pressing (CIP) uses fluid as a means of applying pressure to the mold at room temperature. After removal the part still needs to be sintered. It is the process by which fluid medium especially liquid is preferred as a working medium. It is helpful in distributing pressure uniformly over the compaction material contained in a rubber bag.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Trioxide Optical Property

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:33

Photocatalysis is a new area which developed in recent this year, there are many semiconductor material is used as a photocatalyst for water decomposition. WO3 tungsten ions exist oxygen vacancies which will cause some parts W6 + ions restore to W5 + and oxygen vacancies affect tungsten oxide crystal type and level structure, thus affecting the photocatalytic properties. Non-stoichiometric WO3-X performance n-type semiconductor behavior, the band gap is 2.4 ~ 2.8ev, which also makes its photocatalytic properties better than other semiconductor materials. At wavelengths of UV radiation bigger than 330nm, Fe2 + / Fe3 + electrolyte system, the WO3catalytic powders photolysis rate is 1220umol / g / h. Under 420nm visible radiation, oxygen production rate has reached 320umol / g / h.

When WO3 tungsten ions due to oxygen vacancies causing some parts W6 + ions restore to W5 ions, the electrochromic effect occurs, the color of the material accordingly from light yellow to light green. Injecting external ions and electrons into WO3 materials so W6 + ions and W5 + can reversible. This applications can use in colored and achromatic area.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Trioxide Electrical Properties

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:31

Tungsten trioxide formula is WO3 and a molecular weight is 231.85. WO3 formula is fairly simple, but its physical nature is very complex. Tungsten trioxide satisfies the stoichiometric ratio and no impurities should be colorless and transparent insulator. But the oxygen content of WO3 is usually not meet strict stoichiometric ratio, because it is difficult to control the oxygen content of the preparation, together with other complex factors, the type of WO3-X so represented. In 1959, Sawada and Danielson reported resistivity measurements performed on single crystals WO3 results p = 1.7 × 10-1Ω • cm. In 1983 Sahle and Nygren reported conductivity measurement of WO3-X (0≤y≤0.28)series single crystal. With the study of tungsten trioxide electrical properties we found that for WO3-x single crystals, their electrical properties change with the structure and oxygen content can be separately presented metal or semiconductor behavior. Ferroelectric behavior is an extremely important electrical property of WO3 material. WO3 crystal is a ferroelectric material and the ferroelectric temperature is Tc = -40 ℃.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Using Hydrothermal Crystallization Method Produce Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:30

Tungsten trioxide as a photocatalyst has broad application prospects in terms of the degradation of organic and inorganic materials. Using solid phase calcination method with the different row material APT and H2WO4 the photocatalyst property is different. At high temperatures the APT as raw materials producing hexagonal phase WO3-X photocatalyst has better property.

But the study proved that H2WO4 as raw materials and using hydrothermal crystallization method will produce hexagonal phase WO3-X, oxygen index is 2.50, photocatalytic water splitting performance is greatly improved. Using hydrothermal crystallization method, the raw material will change with increasing temperature. With increasing temperature, the product will be from WO3-X. 0.33H2O converted to hexagonal phase WO3-X and in the development of temperature it will further change to monoclinic WO3-X. At the beginning WO3-X photocatalytic will be changed for the better with increasing temperature, but with the hexagonal phase WO3-X slowly transformed into monoclinic WO3-X, its photocatalytic water splitting performance is slowly reduced. From that we kown with the gradual reduction of oxygen index, WO3-X photocatalytic decomposition of water rate is increased, after reaching the limit there will has a sharp decline. This is means the photocatalytic properties of WO3-X there is an optimum content of oxygen vacancies. When the oxygen index is 2.44 to 2.50, its photolysis rate is high. Therefore hexagonal phase WO3-X will help improve the WO3-X photocatalytic water splitting properties.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Using Solid Phase Calcination Method Produce Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:28

Photocatalysis is kind of catalyst which is used to split water into hydrogen and oxygen. The tungsten ions of tungsten trioxide due to oxygen vacancy so some part of W6 + ions will restore to W5 + ions, oxygen vacancy is the main reason for tungsten trioxide photocatalytic properties. However, due to variation in the valence of tungsten oxide, oxygen is difficult to determine, multi-phase transformation and electrical properties complex so it is hard to sure different crystalline forms of photocatalytic properties.

After several experts study found use solid phase clacination method with APT product WO3-X photocatalyst, mainly by the monoclinic phase, its poor performance on photocatalytic decomposition of water. However, after changing the reaction conditions, its photocatalytic performance can be greatly enhanced. For example, when heated at a temperature of 600 ℃ for 4 hours will produce hexagonal WO3-X, hexagonal WO3-X water photolysis has highest rate of oxygen evolution. With H2WO4 prepared by solid phase of WO3-X photocatalyst are monoclinic phase. And the temperature changes the photocatalytic properties change little. Therefore, using H2WO4 produce WO3-X photocatalyst is bad than using APT at atemperature of 600 ℃ produce WO3-X's.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com