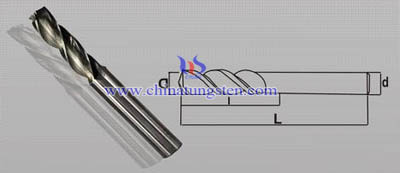

Solid Tungsten Carbide End Mill System Ⅱ

- Details

- Category: Tungsten Information

- Published on Thursday, 29 October 2015 19:04

- Written by zhihua

- Hits: 375

In last part we know that a solid tungsten carbide end mill is in many ways different from an insert milling cutter, such as, they have different types of coatings and substrates, same tolerances but different material stiffness and thus precision levels, and arc of tool contact. Here we go on exploring the characters of solid tungsten carbide end mill system.

Solid tungsten carbide end mills and steel based insert milling cutters have completely different characteristics in temperature handling and this should be reflected in the cutting strategy selection. Considering these facts and putting things further in perspective one has to look at tool dimensions too.

In the smaller diameter range below 10 mm there are very few insert based alternatives to solid tungsten carbide cutters and the choice is clearly going toward solid end mills. The opposite applies for tools with large diameters where solid carbide tools are not a viable choice for economical reasons. This leaves us with the intermediate range of sizes between 10 to approximately 25 mm where many system overlaps exist. The complexity of the shape to be machined, its accessibility and tolerances to be held are the guiding stars for initial tool selection here.

(To be continued. This article is divided into several parts and this is part 2, for part 1 please refer to http://news.chinatungsten.com/en/tungsten-information/79853-ti-10210)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com