Infiltration Temperature Effect on Tungsten Copper Electrode Properties IV

- Details

- Category: Tungsten Information

- Published on Monday, 30 November 2015 17:21

- Written by xiaobin

- Hits: 279

In addition, before reaching optimum infiltration temperature, tungsten particles are distributed more evenly, but copper infiltration is not very uniform, after which the temperature rises, copper dissolution, infiltration sufficient. And the infiltration temperature is too high, tungsten particles connections increased risk, the smaller the tungsten particles grew up together, the copper phase distribution network has been hampered, leading to uneven distribution organization.

Overall, the properties of tungsten copper electrode react sensitively to infiltration temperature, which affected by wetting angle, surface tension, viscosity, capillary force, particle rearrangement, solid phase sintering, liquid phase sintering, particle distribution, coupling rate and so on. Therefore, infiltration temperature plays an important role in tungsten copper electrode properties.

More information about infiltration temperature effect on tungsten copper electrode properties, click here:

http://news.chinatungsten.com/en/tungsten-information/80856-ti-10414

http://news.chinatungsten.com/en/tungsten-information/80857-ti-10415

http://news.chinatungsten.com/en/tungsten-information/80908-ti-10421

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Infiltration Temperature Effect on Tungsten Copper Electrode Properties III

- Details

- Category: Tungsten Information

- Published on Monday, 30 November 2015 17:08

- Written by xiaobin

- Hits: 353

However, with the increasing infiltration temperature, tungsten skeleton sinter in solid phase, which blocks up the rearrangement of particle during the infiltration of copper liquid. The increasing close pores decrease the density of tungsten copper electrode. When the temperature exceeds the limit, tungsten particles will have sintering aggregation. Meanwhile, in the process of infiltration, the surface tension of liquid copper was plummeting copper liquid by capillary force is reduced, resulting in copper liquid overflow.

The hardness of tungsten copper W-25Cu at different infiltration temperature:

The graph shows that the hardness trend is similar to the density trend of tungsten copper W-25Cu, which increases with the increasing temperature at the beginning, and decreases when the temperature exceeds the limit. Due to the hardness of tungsten-copper alloy essentially depends on the density of tungsten copper alloy, for tungsten copper infiltration, before reaching the best temperature, the density of tungsten copper electrode will increase.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Similar to Anviloy 1150

- Details

- Category: Tungsten Information

- Published on Monday, 30 November 2015 16:08

- Written by Cher

- Hits: 451

Tungsten heavy alloy similar to the brand name as Anviloy 1150 is a tungsten-based material with adding a few amount of molybdenum, copper, nickel, iron. With low coefficient of thermal expansion, good thermal conductivity and good material properties, tungsten alloy similar to anviloy 1150 can have less thermal fatigue and soldering in the die cast or extrusion.When the mold has to repeatedly withstand the metal melt at a temperature of over 600℃, we will offer tungsten heavy metal alloy similar to Anviloy 1150 or for your choice.

We will supply tungsten alloy similar to Anviloy 1150 mold inserts, sprue bushes, cooling inserts and other individual parts for die casting, aluminum permanent mold, and difficult extrusions.

| 高比重合金供应商:中钨在线科技有限公司 | 产品详情: http://www.tungsten-alloy.com |

| 电话:0592-5129696 传真:5129797 | 电子邮件:sales@chinatungsten.com |

| 钨钼文库:http://i.chinatungsten.com | 钨钼图片: http://image.chinatungsten.com |

| 钨新闻3G版:http://3g.chinatungsten.com | 钼业新闻: http://news.molybdenum.com.cn |

Feature of Tungsten Alloy Similar to Anviloy 1150

- Details

- Category: Tungsten Information

- Published on Monday, 30 November 2015 16:18

- Written by Cher

- Hits: 321

Tungsten alloy(90%W4%Ni45Mo2%Fe) similat to Anviloy 1150 material is used in electrobrazing applications where head balance is important. The tungsten lloy similar to Anviloy 1150 material also has good anti-sticking qualities and good high temperature abrasion and hardness properties. The oxidation resistance of both material is excellent up to 1100F.

Features:

High temperature resistant capability

Robust external and internal body

Good thermal conductivity

Better surface finish

Corrosion and heat resistance

Ruggedness

Shock resistant capability

Environment friendly

| 高比重合金供应商:中钨在线科技有限公司 | 产品详情: http://www.tungsten-alloy.com |

| 电话:0592-5129696 传真:5129797 | 电子邮件:sales@chinatungsten.com |

| 钨钼文库:http://i.chinatungsten.com | 钨钼图片: http://image.chinatungsten.com |

| 钨新闻3G版:http://3g.chinatungsten.com | 钼业新闻: http://news.molybdenum.com.cn |

Infiltration Temperature Effect on Tungsten Copper Electrode Properties II

- Details

- Category: Tungsten Information

- Published on Friday, 27 November 2015 16:51

- Written by xiaobin

- Hits: 360

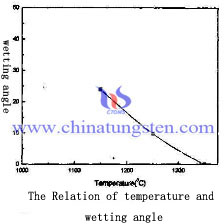

Infiltration temperature controlling is crucial in the process of tungsten copper electrode, its rise and fall has a great effect on comprehensive performance of tungsten copper electrode. There is a graph of the relation of infiltration temperature and wetting angle as follow.

The graph remarkably shows that infiltration temperature plays an important role in diffusion effects. The higher Infiltration temperature, the smaller the infiltrate angle, easily viewed from the figure, the wetting angle decreases with increasing temperature, the surface tension increases with increasing temperature. Theoretically, when the temperature is 1350 ℃, θ = 0°, completely molten copper and tungsten wetting at this time, the infiltration effect is best. And the copper liquid viscosity decreases with increasing temperature, so the temperature can be increased to improve the infiltration of liquid copper flowability, enhanced capillary action, be conducive to infiltration.

More information about infiltration temperature effect on tungsten copper electrode properties, click here:

http://news.chinatungsten.com/en/tungsten-information/80856-ti-10414

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com