Nano Precious Metal Modified Tungsten Trioxide Photocatalyst Coating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 May 2016 18:06

- Written by chunyan

- Hits: 223

There are many kinds of photocatalyst materials, including titanium dioxide, zinc oxide, tungsten trioxide ect.. Wherein, titanium dioxide has become the world's most popular photocatalyst nano material, because of its strong oxidizing ability, chemically stable with non-toxic. In theory, a wavelength light less than 380nm can stimulate anatase titanium dioxide, bringing the photocatalytic effect. Of course, as technology advances, the boundary of 380nm has long been a breakthrough, photocatalyst products even response under visible light have been found.

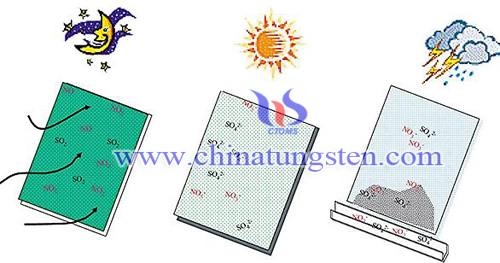

The band gap of tungsten trioxide is 2.kV, as a photocatalyst responded to visible light, it has a wide range of applications with its small harmful and cheap. However, due to technical limitations, tungsten trioxide photocatalyst products on the currently market are ineffective with poor photocatalytic effect. Accordingly, inventing a method to preparing photocatalyst coating with higher reactivity and can be large-scale industrial produced is particularly important.

1. Add noble metal salt and aqueous solution into strong base solution according to a certain percentage, heating for reacting and then cooling to obtain a nano noble metal solution, wherein the noble metal can be Pt, Au, Pd, or Ag, preferably of nano Pt;

2. Add the tungsten trioxide powder according to established ratio into the deionized water, then ultrasonic dispersion for 0.8-1.2h;

3. Add a strong acid (hydrochloric acid or sulfuric acid) into the solution obtained in step 2, control the pH value at 2 to 5, and then continue to ultrasonic dispersion for 0.8~1.2h;

4. Add the nano-noble metal solution to ultrasonic dispersion for 20-40min, then get the nano precious metal modified tungsten trioxide photocatalyst coating.

This kind of photocatalyst coating has a high reactivity, and you can get high activity visible light responsive photocatalyst coating film after drying the spray layer; with the simple preparation method, process stability, no need of photocatalytic reduction, it is suitable for large-scale Industrial production.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com