WO3 Denitration Catalyst Regeneration - Bubble Flow Device Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 May 2016 17:10

- Written by chunyan

- Hits: 231

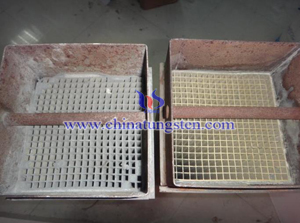

In the running, tungsten trioxide denitration catalyst will part or entire inactivated due to the fly ash poisoning and deposition of solids ect., and end its life after a certain period of time (approximately 2 to 5 years), therefore needs to be regenerated or obsolete processed. The bubble flow device (Air Lift Loop Reactor) can recover the activity of honeycomb SCR catalyst which deactivated from heavy metal poisoning in fly ash and solids deposition pollution ect. to the activity before polluted.

In the running, tungsten trioxide denitration catalyst will part or entire inactivated due to the fly ash poisoning and deposition of solids ect., and end its life after a certain period of time (approximately 2 to 5 years), therefore needs to be regenerated or obsolete processed. The bubble flow device (Air Lift Loop Reactor) can recover the activity of honeycomb SCR catalyst which deactivated from heavy metal poisoning in fly ash and solids deposition pollution ect. to the activity before polluted.

Most honeycomb-type SCR catalysts take titanium dioxide as the carrier, with the main active ingredient of organic and inorganic binders of vanadium (1~3%) and tungsten (10-20%). Experiment uses the mixture solution of sulfuric acid, ammonium vanadate and ammonium paratungstate to carry out the catalyst regeneration by bubble flow device, which the steps are showed as bellows.

1. Install the inactivated tungsten trioxide denitration catalyst in the bubble flow device, then washing for about 1 hour with the mixture solution of sulfuric acid which generated by pure water at room temperature, ammonium vanadate and ammonium paratungstate;

2. Dry the washed catalyst at a high temperature of 200°C in the air;

3. Calcined to obtain the regenerated tungsten trioxide denitration catalyst.

Remarks:

1. When weight content of the active ingredient- vanadium pentoxide less than 1.0%, the NOx removal rate is very low; however, when it reaches 10% or more, the NOx removal will decline rapidly at the high temperatures above 400°C, and promote the oxidation of sulfur dioxide, therefore, the selection of ammonium vanadate solution shall base on the vanadium pentoxide content which is controlled among 1.0~10%.

2. When the content of active ingredient- tungsten is higher than 20%, the oxidation of sulfur dioxide will be promoted, and the price is very expensive, therefore, the selection of appropriate concentration of ammonium paratungstate solution will be suggested to the economic.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com