Tungsten Carbide Staggered-edge End Mill (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 25 March 2016 17:38

- Written by xiaobin

- Hits: 249

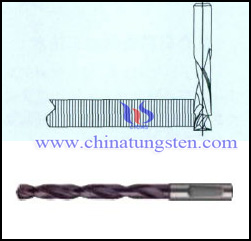

Generally, due to the cutting force of down milling, the workpiece is pressed against the table so that it is a priority, unless there is a thread gap or other problems considering up milling. Based on this theory, the relevant researchers have proposed the idea of tungsten carbide staggered-edge end mill. Compared with conventional D-edge end mills, tungsten carbide staggered-edge end mill has D-proximal portion, near the handle L-interleaved design, which the original design concept is intended to apply to new carbon fiber composite material. The specific design schematic diagram shown as follow:

From the schematic above we can clearly see that tungsten carbide staggered-edge end mill has two parts, the workpiece processed should be in the middle area between the two cutting edges. Due to the cutting edge is used in the proximal portion of the edge right-handed, left-handed edge near the handle of the staggered design, the lower section of the right-handed cutting edge of the lower surface of the workpiece can be milled, while at the same time under the surface but also by the upward the cutting force; on the contrary, the upper surface of the upper left-hand cutting edge end mill for milling a workpiece and produces its downward cutting force.

In the overall cutting process, the mill closely pressed against the workpiece and feed, so the fiber layer top and bottom surfaces of the material are more likely to be cut off, which effectively avoid the workpiece upper and lower surfaces tears, burrs and other processing defects. In addition, Since the upper and lower surfaces of the workpiece by the cutting force component perpendicular to the contrary, the axial force is reduced and the overall direction of the cutting force is moderate, toward the inside of the workpiece, which is conducive to smoothly throughout the cutting process, but also inhibit stratified of the inner portion of the workpiece. It is possible to improve processing quality carbon fiber composite material to a certain extent. The milling test shows that under the same cutting conditions, grain wear is the main pattern of tungsten carbide staggered-edge end mill. And compared with conventional tungsten carbide end mills, it has better wear resistance and service life.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com