Effect of Powder Property on Tungsten Copper Electrode Density (2 of 2)

- Details

- Category: Tungsten Information

- Published on Monday, 11 January 2016 17:40

- Written by xiaobin

- Hits: 324

Relevant foreign scholars have studied the densification process high-density tungsten alloy found W-Ni-Fe high density alloys, when the average particle size of the tungsten particles is 1μm, occurred at about 1200 ℃ rapid densification; when the tungsten particles have an average particle size of 5μm, at 1400 ℃ was undergoing rapid densification. It indicates that decreasing the granularity of powder and increasing the superficial area can remarkably decrease the sintering temperature of powder press.

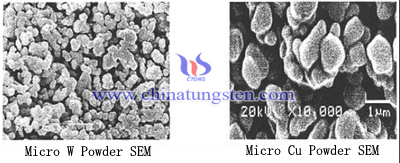

In addition, the appearance of powder particles has an influence of densification processing. If the shape of the powder particles exhibit uneven shape it is easy to bypass the formation of voids between the particles and increases the friction powder and die wall, between the powder particles, which will not help to improve the sintered density after the bulk material. The higher the degree of spherical particles, the better mobility, it is easily to fill the cavity so that bulk density, but also conducive to pressing and sintering, to obtain a higher density. Nano tungsten powder and nano copper powder SEM image as follow:

Viewed from the SEM image, we can find that micro Cu powder particle has more regular shape and high sphericity; compared with micro Cu powder, micro W powder particle is more irregular, it is polygonal and has low sphericity, which is not beneficial for tungsten copper electrode with high density manufacturing. Furthermore, micron tungsten powder and copper powder having a large surface area and the ratio of the excess surface energy, in a state of energy imbalance, has a high activity, favor the sintering process. Cu particles has good plasticity and soft texture, easily deformed during pressing and help to increase the contact area between the particles so that the tungsten copper electrode material density may be improved; however, W particles has high melting point, high hardness, low plasticity, it is not easily to be out of shape and fractured, which is not beneficial for the density improving.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com