Facts About Tungsten Carbide Burs (2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 14:16

- Written by lucy

- Hits: 432

Shank Sizes

The shank of tungsten carbide burs refer to the end of the bur that contacts with rotary tool. The popular shank sizes in markets including, 1.6mm, 2.35mm, 3mm and 6mm.

Shapes

The different shaped tungsten carbide burs could fit into different nook and cranny to generate distinctive profiles. Generally the burs shapes to be chose largely depend on the the profiles are aimed.

Speed

In terms of tungsten carbide burs’ rotary tools speed selection, the attention should be paid to the materials to be operated on and the forms being made. The recommended speed is within 35,000rpm. If the speed is too slow, the burs are easily to be fractured, whereas it is better to set up with slow speed and increasing the speed as the process going on. For the high speeds it could make effort in preventing clogging in the flutes.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Facts About Tungsten Carbide Burs(1)

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 14:15

- Written by lucy

- Hits: 439

Tungsten carbide bursare used to deal with cutting, shaping, grinding and removing the sharp edges, burs and excess material in practices and end mills for metalworking as well as for holes of all sorts. There are several facts related to its geometry and characteristics can be addressed.

Material to Be Machined

As tungsten carbide tools maintain a sharp cutting edge better than others, the tungsten carbide burs could be dealt with most hard materials: metals including steel, aluminum and cast iron, stone, ceramic, porcelain, hard wood, acrylics, fibreglass and reinforced plastics.

Single Cut and Double Cut

Tungsten carbide burs usually comprises single cut and double cut. Since single cut tungsten carbide burr has a up cut spiral flute, which could get rid of material quickly with a smooth finish, it is an ideal solution for steel, copper,cast iron and ferrous metals.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tipped Annular Cutter Benefits (2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 14:05

- Written by lucy

- Hits: 372

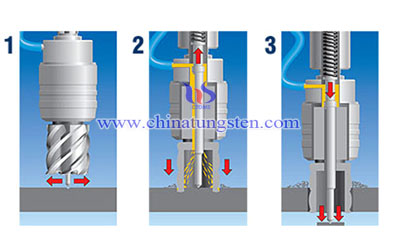

Energy Saving

Differently from the conventional drill bits, which has to cut through complete work pieces, the tungsten carbide annular cutter only removes the material on the periphery of hole. Since it requires less drive, the relevant energy requirement is less.

More Finishing

It proves that, by adopting tungsten carbide annular cutter in hole making, the result benefit in more finished , precise and accurate.

Efficient Cooling

The tungsten carbide annular cutter is internal cooling. With the help of a pilot pin, its internal lubrication is offered via the hollow body, which ensures more efficient and faster operation during the deep hole drilling.

Easy

Since the annular cutters have distinctive geometry, it could ease the awkward angles’ hole making.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tipped Annular Cutter Benefits (1)

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 14:05

- Written by lucy

- Hits: 423

Tungsten carbide tipped annular cutter is a cutting tool, made from tungsten carbide material on its tip, with multiple cutting edges and hollow body. Besides it owns advantages of extreme hardness and durability, it is also identified benefits in time saving, energy saving ,more finishing and etc..

Time Saving

Compared to conventional drill bits, the tungsten carbide tipped annular cutters are supposed to be 3 to 4 times faster, and instead of removing the complete material of the hole, the tungsten carbide annular cutter only has to eliminate less material, due to its cuts simply on the periphery of the hole. Furthermore, differently from conventional drill bits, annular cutters are one-shot operation,which do not need pre-drilling. The less teeth design also offers annular cutters’ hole making in higher speed and faster feed rate.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Trioxide Main Phase During Reaction Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 08:59

- Written by xiaoshan

- Hits: 415

Many studies have shown that tungsten powder largely depends on the final size of the tungsten oxide and reducing conditions. During the reduction process tungsten trioxide (WO3) major phase component has a great influence on the grain size of tungsten powder, to understand the main phase ingredients of restore process in favor of to choose different raw materials and processing technology to produce different size tungsten powder (WP). After studies found that when the temperature at 500 ~ 600 ℃, the tungsten trioxide reaction occurs as WO3 → β- tungsten oxide → β-W → WP. And there are a small amount of β- tungsten oxide turn into tungsten dioxide (WO2), and then reduced to WP. When the reaction temperature is 600 ~ 800 ℃, the reaction as follow WO3 → β-tungsten oxide → dioxide, →tungsten dioxide → WP. In which a small amount of β- tungsten oxide restore to β-W and then into WP. When the temperature is 770 ~ 900 ℃, the reaction occurs as WO3 →β-tungsten oxide→ γ- tungsten oxide→tungsten dioxide→ WP. Besides after the morphological study found that tungsten trioxide is good for produce coarse particles tungsten powder, γ- tungsten oxide is suitable to obtain fine tungsten powder, β- tungsten oxide is somewhere in between.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com