Common Coatings for Tungsten Carbide End Mill

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 15:19

- Written by lucy

- Hits: 1301

On the market today , for tungsten carbide end mill, the well accepted common coatings comprise Titanium Nitride (TiN), Titanium Carbon Nitride( TiCN) and Aluminum Titanium Nitride (AlTiN) , as well as Titanium Aluminum Nitride (TiAlN).

Since the coatings like AlTiN and TiSAlN have extra aluminum content,which are more effective at evacuating heat, they are more popular in end mill applications. Specially ,both TiAlN and AlTiN is a thin film coating that was delveloped from Titanium Nitride. It is recommended that when machining aluminum, brass, plastics and other nonferrous materials it is better to use AlTiN or TiAlN coated end mill with polished flutes to prevent edge buildup.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

TiAlN Coated Tungsten Carbide End Mill

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 15:18

- Written by lucy

- Hits: 429

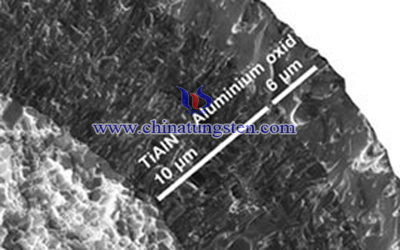

Since the TiAlN is a thin film coating that was developed from Titanium Nitride with more aluminum content, TiAlN coated tungsten carbide end mills are more effective in heat removing and higher heat resistance.

During the milling processes, the temperature of the cutting edge could soar up to 1800°F , which would make tungsten carbide end mill suffer from damaging effects of heat. However, with the TiAlN coating, the aluminum in the coating provides a gaseous aluminum oxide layer for the cutting edge. In addition, the dry machining is recommended, as the heat is removed so well into the chips with TiAlN coating, and the high-speed or hard milling is also ideal match with TiAlN coated tungsten carbide end mill.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Milling Cutters Coatings

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 15:15

- Written by lucy

- Hits: 390

In order to get a better milling performance and longer tool life, coating is a vital process for the tungsten carbide milling Cutter to resist wear and heat. It is indicated that coatings enable the tungsten carbide milling cutters to remove the cutting chips from the flutes, as well as the end mill’s ground surface.

In nowadays, the hard coatings for cutting tools int terms of commercial acceptance is driven by demands on machining productivity, environmental protection and up to date hard materials. Improved cutting performance is derived from synergies of machine tool system and cutting tool development. The latter strives for an optimized combination of tool material, hard coating and cutting edge geometry. As a result the cutting-edge technology offer more heat- and wear-resistant coatings has promoted longer tool life and increased productivity.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

AlTiN Coated Tungsten Carbide Milling Tools’ Features

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 15:16

- Written by lucy

- Hits: 418

It is known that the AlTiN is a thin film coating that was developed from Titanium Nitride with more aluminum content, which enables AlTiN coated tungsten carbide milling tools offer higher temperature resistance than the ones with TiN, as well as slightly higher hardness and especially higher hot hardness. In general, the advantages of AlTiN coated tungsten carbide milling tools comprise as follow.

It proves that AlTiN coated tungsten carbide milling tools could withstand elevated temperatures up to 800°C in air. It operates well in high temperature applications, as it could offer an outstanding bound-a low in friction and oxidation resistant thin Al2O3 surface layer, which could constantly rebuilt and require high temperatures to form. AlTiN coated tungsten carbide milling tools typically last 3 to 10 times longer than uncoated tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cutting Ring Method on Residual Stress Measurement of Tungsten Tube

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 14:08

- Written by Yahong

- Hits: 374

Cutting ring method is one of the methods for measuring the residual stress of tungsten tube, which is implementing by measuring dependent variable before and after the cut, the average distribution of residual stress thereby overall reflected.

Cutting ring method steps:

Taking deposition samples →obtaining the cutting ring by cutting the samples in the axial direction → removing the deposition matrix →cutting tungsten tube in the axial direction to get cutting ring → vacuum annealing (temperature of 1200 ℃, holding time of 1h) to get cutting ring

The incision of tungsten tube got after the removal of deposition matrix and the cut along the axial direction is significantly reduced, indicating that in the subsequent cooling process, shrinkage of deposition matrix produce great residual stress in tungsten tube, and the residual stress is present in the circumferential direction of tungsten tube. The residual stress decreases with the deposition temperature increases and the deposition of tungsten tube diameter increases.

After vacuum annealing, change of annular incision diameter is not obvious.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com