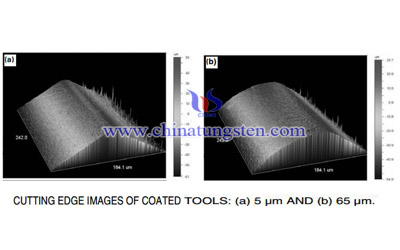

Cutting Edge Geometry Effects On Tungsten Carbide Inserts Coating Process

- Details

- Category: Tungsten Information

- Published on Friday, 03 July 2015 14:56

- Written by lucy

- Hits: 381

In practical machining application, it has been pointed out that the cutting edge geometry has compound effects on tungsten carbide inserts coating process, and the cutting edge radius affects the deposition stresses and machining loads in an opposite way. Specially, under different cutting condition, the optimal radius maybe varied from one to another since the edge radius effects on machining loads are depended on machining parameters.

In the coating process like CVD processes, the thermal mismatch between the coating and substrate materials are likely to generate high residual stresses in the tool, and for the tungsten carbide insert’substrate, the cobalt cemented tungsten carbide receive a tensile stress, which tends to have impacts on the coating functions. Moreover, the geometric changes like cutting edges, will severely alter the local stress fields.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Solvent Extraction &Ion Exchange Method

- Details

- Category: Tungsten Information

- Published on Friday, 03 July 2015 14:54

- Written by Cristina

- Hits: 357

Use sodium tungstate solution as raw material, preparing ammonium metatungstate solution by solvent extraction or ion exchange. Solvent extraction and ion exchange which is basically the same process and the preparation of ammonium paratungstate. The difference is in the back-extraction (or desorption) operation, stripping agent (or desorbent) and amount of different concentrations in the solution was maintained at pH 3 to 4 cases, back-extracted (or desorption) obtained metatungstate ammonium solution. This method in general APT production process, unnecessary use of stripping agent (or desorbent) can be produced under conditions of AMT solution, so it is a simple method.

Ammonium tungstate solution as a raw material by solvent extraction or ion exchange, then the cationic extractant (or a cation exchange resin) and extracted (or adsorbed) ammonium tungstate solution [NH4] + ion, and then with a suitable stabilizer and can output under the condition of pH AMT solution, which is both simple and economical method. Ammonium metatungstate solution solvent extraction or ion exchange method was the same concentrated crystals or spray drying to take ammonium metatungstate products.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Doping Tungsten Influence Vanadium Dioxide’s Phase Temperature

- Details

- Category: Tungsten Information

- Published on Friday, 03 July 2015 14:51

- Written by xiaoshan

- Hits: 336

Vanadium dioxide film is a new type of heat-sensitive functional materials. It is with increasing temperature at about 68 ℃ will change from semiconductor monoclinic rutile structure to metallic state tetragonal rutile structure. Besides the resistivity and infrared light transmittance and other physical properties are also mutated, based on this characteristic, it is widely used in optical data storage, optical switches and smart windows and other fields. However, due to the phase transition temperature of vanadium dioxide is too high to be widely used. After the studies found that the incorporation a small amount of tungsten ions in vanadium dioxide film can effectively reduce the phase transition point of the film, which is conducive to tungsten vanadium dioxide film be applied in more areas.

Vanadium dioxide doping tungsten cause phase transition temperature lower there are two interpretations, the first one is because when the metal - semiconductor phase transition the vanadium atoms of lattice center off center octahedral voids, then tungsten which has larger atomic radius replace vanadium atoms, however, vanadium octahedral body no extra space for tungsten atoms from the center so as to stabilize the vanadium dioxide metal phase. The second explanation is tungsten has more than two d electrons into V3d vanadium, making the band gap of the semiconductor phase decreases.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Single Crystal Ammonium Paratungstate Preparation

- Details

- Category: Tungsten Information

- Published on Friday, 03 July 2015 14:52

- Written by Cristina

- Hits: 362

The crystal properties of ammonium paratungstate like crystal morphology, average particle size, particle size distribution, apparent density and flow ability affect the properties of tungsten powder, tungsten wire and tungsten alloy. Single crystal ammonium paratungstate due to its eminent physical properties has become ideal raw materials for preparing tungsten products.

Based on crystallization theory of single crystal ammonium paratungstate, the influences of crystallization device, stirring speed, temperature on crystallization agglomeration of ammonium paratungstate were studies. The results show that the optimal stirring speed is determined as 30, 50, 70r/min, respectively in different developmental stages of crystallization. Under optimal conditions, single crystal rate arrives to optimal value. Suitably reducing pre-crystallization temperature, single ammonium paratungstate crystal rate has more space for enhance. When crystallization temperature is 80 degree Celsius, crystal rate was 96% to achieve the best value. The fluid layer flow control technology and devices for single ammonium paratungstate crystal preparation can effectively reduce collisions between grains, so that the ammonium paratungstate powder single crystal rate can arrive at more than 90%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Synthesis of Sodium Tungstate From The System Na2 C2 O4 -NaNO3 -WO3

- Details

- Category: Tungsten Information

- Published on Friday, 03 July 2015 14:48

- Written by xinyi

- Hits: 362

The physicochemical basis of the heterogeneous reaction between the components of the system (sodium oxalate)-(sodium nitrate)-(tungsten(VI) oxide) has been studied. The reaction of WO3 with sodium oxalate-nitrate mixtures occurs at a lower temperature and at a higher rate than the reaction with pure sodium carbonate. A high-yield process for the synthesis of high-purity sodium tungstate has been developed on the basis of this study.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com