Ammonium Paratungstate Calcination

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 14:07

- Written by Cristina

- Hits: 337

Ammonium paratungstate calcined in air change course: T ≥ 240 ℃, and transferred as ammonium metatungstate (AMT).

When the temperature is between 300 ~ 350 ℃, it turns into ammonium tungsten bronze ATB. When the temperature is under 400 ℃, it turns into the hexagonal WO3. When the temperature reaches to 500 ℃, it becomes triclinic crystalline tungsten trioxide.

Ammonium paratungstate purity and crystalline are hereditary. Calcination temperature, speed has a significant impact on the physical and chemical properties of the product.

The higher the calcining temperature, the more coarse particle size of the obtained WO3. Rapid heated will cause the larger specific surface area. Slowly heated which results in the perfect crystalline and smaller specific surface area.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Prepared by Liquid Membrane

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 14:05

- Written by Cristina

- Hits: 359

The alkaline feed of crude sodium tungstate obtained from the caustic fusion of black tungsten ore was neutralized to a pH value near 9 to eliminate Si as routine, then the resulting feed was directly used as the external aqueous phase without eliminating P, As and Mo.

Through a single stage batch liquid membrane process at room temperature for 5 min under optimum operation conditions obtained by an orthogonal test, ammonium paratungstate directly crystallizes in the internal aqueous phase with 99.87% yield and the quality attained was the first grade of a national standard; meanwhile the pH value of the effluents was lowered to 6–7 in itself suitable for direct discharge and without W (VI) lost out of the raffinate. Finally, a continuous counter-current process of a single stage for a pilot plant was proposed.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Hexahydrate

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 14:01

- Written by Cristina

- Hits: 361

The crystallization of ammonium paratungstate tetrahydrate, ((NH4)10OH2W12O42·4H2O, APT·4H2O) from aqueous ammonium tungstate solutions is a key unit operation in current tungsten powder production. Ammonium paratungstate hexahydrate (APT·6H2O) can form under conditions where APT·4H2O forms as well. Based on this information it was postulated that APT·6H2O is metastable. Experiments were carried out to determine whether and under what conditions the hexahydrate is metastable.

It was found that the hexahydrate is metastable at a solution concentration of approximately 300-230 g/kg WO3 and from approximately 90° to 96°C. APT·6H2O is not formed when APT·4H2O seeds are added prior to crystallization. It was found that the recrystallization of APT·6H2O into APT·4H2O is prompted by a decreasing water activity in solution during crystallization. The increase in solution temperature during isobaric crystallization also stimulates the recrystallization process. In industrial practice some residual crystals are always present in the crystallizer. Therefore, APT·6H2O will not form during industrial crystallization.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Tungstic Acid Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 14:03

- Written by Cristina

- Hits: 372

Ammonium paratungstate (or APT) is a white crystalline salt of ammonium and tungsten, with the chemical formula (NH4)10(H2W12O42)·4H2O.

Method using ammonia tungstate tungstic acid dissolved, add a boil deionized water. In the stirring, heating by ammonia, Ph value is 8, in the boiling solution by adding acetic acid, and then use the dilute nitric acid. The Ph value is adjusted to 2 ~ 4, continuing heating concentrated to a relative density of 1.5 ~ 2, stop heating, cooling and filtering. The filtrate is added with ethanol. Stir, settlement after filtration, crystal at 80 ℃ drying, pulverizing to obtain the product.

Ammonium paratungstate is used as a source for high-purity tungsten oxides, tungsten metal powders, carbides, or as a laboratory reagent. Also tungsten powder including tungsten trioxide, tungsten blue oxide.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Copper Tungsten Heat Sink Definition

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 12:00

- Written by renge

- Hits: 374

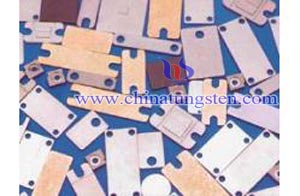

Tungsten copper heat sink is a composite of tungsten and copper. The coefficient of thermal expansion (CTE) of the composite can be designed by controlling the content of tungsten, matching that of the materials, such as Ceramics (Al2O3, BeO), Semiconductors (Si), Metals (Kovar), etc. The products are widely application in the fields such as radio frequency, microwave, high power diode packaging and optical communication system.

Tungsten copper heat sink is a heat base which is made of tungsten copper alloy. A heat base is a term for a component or assembly that transfers heat generated within a solid material to a fluid medium, such as air or a liquid. Examples of heat bases are the heat exchangers used in refrigeration and air conditioning systems and the radiator (also a heat exchanger) in a car. Heat bases also help to cool electronic and optoelectronic devices, such as higher-power lasers and light emitting diodes (LEDs).

Advantages: High thermal conductivity, Excellent hermetic, Excellent size control, surface finish and flatness, Semi-finished or finished (Ni/Au plated) products available properties of WCu and MoCu heat materials.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com