Radiation Shielding Efficiency of Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:38

- Written by wenjing

- Hits: 389

Tungsten alloy is a tungsten-group sintered alloy consisting of tungsten and a binder phase with nickel, copper, iron, etc. Tungsten alloy is also used as radiation shielding material because of its excellent radiation shielding effect realized by its high density. Recently, due to environmental requirements, Tungsten alloy has attracted attention as replacement for lead which has been used for this application.

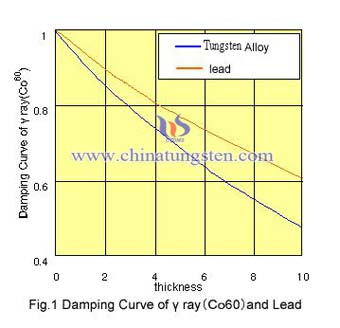

On the radiation shielding effect of tungsten alloy, we examined a comparative evaluation with lead. Fig.1 shows the attenuation rate of γ-ray (Co60) against the change in thickness of tungsten alloy and lead. The γ-ray (Co60) used for the evaluation this time is that eradiated from relatively a high energy zone, which becomes an issue in the case of nuclear power station.

This evaluation proves that tungsten alloy of about 3mm or 7mm thickness has the radiation shielding effect equivalent to lead of about 4.5mm or 10mm thickness respectively. consequently, tungsten alloy, compared with lead, has 1.5 times shielding effect against γ-ray (Co60).

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Tungsten Isotope Radiation Container

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:36

- Written by wenjing

- Hits: 407

Radioactive isotope called "radioisotopes." Isotope radiation technology now widely used in industry, agriculture, health, archeology, and environmental protection and other aspects, including radiation detectors, radiotherapy apparatus and medical X-ray instruments. The most important component of radiation technology equipment is the radiation shielding container. When using radiation technology, place radioactive isotope within the shielding container is the most important thing. Due to its high density, excellent absorption behaviour against radiation and environmental friendly characteristics, tungsten material can be widely used to produce isotope radiation container.

Applications of tungsten isotope radiation container:

Industrial instrumentation equipment and petroleum drilling

Cancer treatment equipment

Weld inspection

Large container inspection equipment

Nuclear submarine accessories

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sodium Polytingstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:17

- Written by xiaoshan

- Hits: 335

Sodium polytingstate are also known as sodium metatungstat. Its physical properties are as follows: chemical formula: Na6O39W12, molecular weight: 2968, density: 3.1g/cm3, CB number: CB1128947, CAS number: 12141-67-2.

Sodium Polytingstate because of its high density, non-toxic, easy preparation and can be recycled and other advantages so it has been widely use in many areas. For example sodium polytingstate wildly use in density separation research area of geology, soil science and marine biology. In geology it is mainly used in separation minerals and sedimentary rocks, for the separation of micro-fine pure minerals providing a new way. In soil science it is mainly used in separate large particles of soil aggregates, organic matter and humic acid and so on. In marine biology and is mainly used in the separation of ancient microbial and organic matter. On the other hand, using sodium polytingstate solution to density separation the operation is simple and the effect is stable. What’s more it not changes the physical and chemical properties of substances to be separated.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Process Test of Copper-Bismuth Separation from Sulfide Minerals Associated With Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:21

- Written by xinyi

- Hits: 331

This paper studies the process test of copper-bismuth separation from sulfide minerals associated with tungsten ore by applying the combined process of gravity separation,flotation and gravity separation.The results of small closed-circuit test: the copper concentrate with the grade of 25.03 % and the recovery of 93.93 %;the bismuth loss rate in the copper concentrate is 7.08 %;the bismuth concentrate with the grade of 15.08 % and the recovery of 79.42 %;the copper loss rate in the bismuth concentrate is 1.84 %.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Simulation and Analysis on Flow Field in Leaching Tank With Dual-impeller for Alkali Cooking Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:14

- Written by xinyi

- Hits: 327

Simulation and Analysis on Flow Field in Leaching Tank With Dual-impeller for Alkali Cooking Tungsten Ore

Computational fluid dynamics method was applied to study three-dimensional flow field in leaching tank with JH type axial impeller and straight blade impeller.The velocity field,pressure field and turbulent kinetic energy field in leaching tank were analysized rotating at constant speed of 300 r/min and taking the fluid of sodium hydroxide mixed with tungsten ore as simulation object by using the multi-reference frame(MRF) and standard k-ε turbulent model.The research provided scientific basis for structure optimization design of leaching tank.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com