Why Does the Cold Resistance of EB Tungsten Filament Unqualified?

- Details

- Category: Tungsten Information

- Published on Thursday, 14 April 2016 17:36

- Written by xuejiao

- Hits: 307

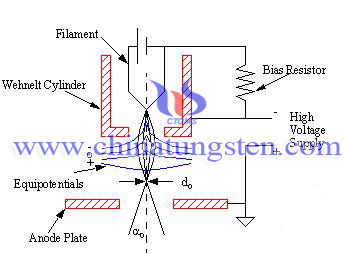

In China, the main material of EB (electron beam) tungsten filament is Double spiral wire. Double spiral wire can heating the cathode evenly. What’s more, the Double spiral wire can eliminate the influence of the magnetic field which is cause by the cathode electron beam. However, the process to make the Double spiral wire is more complex, if the users cannot operate dissolution of molybdenum correctly, it will cause a lot of substandard products. Against to the unqualified phenomenon of the cold resistance of EB tungsten filament, people should try to improve the process of molybdenum core wire dissolution.

Molybdenum core wire dissolution is a pure chemical reaction process. Molybdenum has a strong chemical stability, so that people used a mixture of concentrated sulfuric acid, concentrated nitric acid and water as an etching solution. During the reaction, the temperature and time of the reaction should be to control by a strict operation. In addition, people should also pay attention to the phenomenon of the reaction, the reaction speed would change for the different temperature and the seasons. Due to the low temperatures in winter, the reaction is difficult to control the, it is more likely to cause the cold resistance of EB tungsten filament unqualified.

There exist the remaining acid in the surface of EB tungsten filament without washing cleanly. Oxidation would make the tails of EB tungsten filament become black. Molybdenum wire of cold resistance of EB tungsten filament is mainly caused by the incomplete reaction.

The cold resistance of EB tungsten filament unqualified will produce a lot of waste, causing serious environmental pollution. Therefore, people need to understand the reason to reduce pollution and improve the ecological environment.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Maintenance of EB Tungsten Filament of SEM

- Details

- Category: Tungsten Information

- Published on Thursday, 14 April 2016 17:33

- Written by xuejiao

- Hits: 356

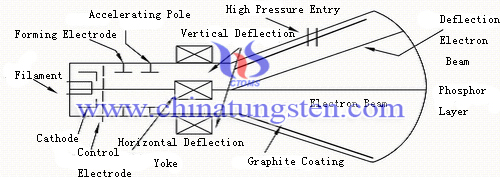

SEM (scanning electron microscope) of the electron microscope has a lower degree of vacuum, and a large beam current. Therefore, the life time of tungsten filament of SEM is limited. Generally speaking, it can last for only a few dozen hours. The life time of tungsten filament of SEM has a direct impact on the cost of the instruments operation and the effective time of operation. Consequently, it would cause more pollution and other adverse consequences. Therefore, the tungsten filament of SEM needs a regular maintenance or repair. Users can take the following measures to maintain tungsten filament and extend the life time of instruments.

Firstly, check the condition of tungsten filament, if possible, users should put the component of tungsten filament on the dissecting microscope to check again. The rate of evaporation of the filament surface is related to the temperature of the filament, users can adjust a higher height to decrease the temperature of the filament. The material can choose a thick filament gasket. And then users should adjust the current of tungsten filament. During the maintenance of tungsten filament of SEM, users should check the saturation of the filament timely. Under an unsaturated condition, current of tungsten filament should be adjusted to the saturated condition. Finally, keep the vacuum degree of Scanning electron microscope lens.

Other measures to maintain tungsten filament of SEM are: 1. Before exchange the filament, users should remove dampness and air of the new filament. 2. Do not switch filament frequently in the daily work.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Prevent WO3 Waste Flue Gas Denitration Catalyst Regeneration Pollution

- Details

- Category: Tungsten Information

- Published on Thursday, 14 April 2016 17:15

- Written by chunyan

- Hits: 248

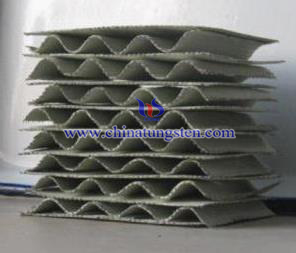

At present, the NOx in China is mainly coming from coal-fired power plants, tungsten trioxide SCR denitration catalyst is widely used as the best denitration technology due to the nice properties such as high denitration rate, selectivity, mature and reliable. However large numbers of toxic and hazardous waste gas tungsten trioxide denitration catalysts are produced with the ongoing SCR project. Therefore, strengthening the management of waste gas denitration catalyst for preventing human health and environment being damaged is necessary.

At present, the NOx in China is mainly coming from coal-fired power plants, tungsten trioxide SCR denitration catalyst is widely used as the best denitration technology due to the nice properties such as high denitration rate, selectivity, mature and reliable. However large numbers of toxic and hazardous waste gas tungsten trioxide denitration catalysts are produced with the ongoing SCR project. Therefore, strengthening the management of waste gas denitration catalyst for preventing human health and environment being damaged is necessary.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

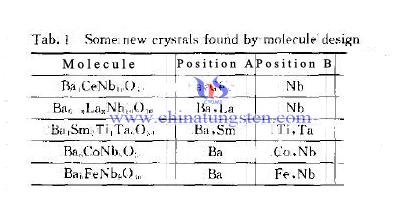

Tungsten bronze (TB) Crystal Material Molecular Design

- Details

- Category: Tungsten Information

- Published on Thursday, 14 April 2016 17:31

- Written by xinyi

- Hits: 298

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Commercial Recovering Value of Waste WO3 Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 14 April 2016 17:12

- Written by chunyan

- Hits: 232

There are a large number of valuable metals in the waste SCR denitration catalyst, if directly discarded, it will cause a huge resources waste; furthermore, vanadium pentoxide can cause environmental pollution because of its highly toxic. For reducing environmental pollution caused in denitration catalyst regeneration process, to establish a program for generating material with high content of valuable metals, and its products can be sold directly as a raw material thus to have some commercial value.

There are a large number of valuable metals in the waste SCR denitration catalyst, if directly discarded, it will cause a huge resources waste; furthermore, vanadium pentoxide can cause environmental pollution because of its highly toxic. For reducing environmental pollution caused in denitration catalyst regeneration process, to establish a program for generating material with high content of valuable metals, and its products can be sold directly as a raw material thus to have some commercial value.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com