Reasons for the Crack of Tungsten Crucible Bottom

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:30

- Written by xuejiao

- Hits: 382

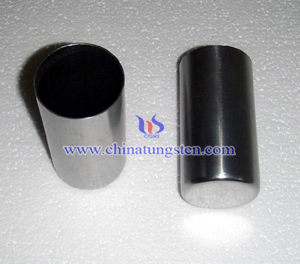

As the main tungsten product, tungsten crucible is widely applied in smelting of rare earths and the demand of it is also increasing for rare earth industry. However, the crack of tungsten crucible bottom will directly influence in the rate of finished tungsten crucible products during the productive process. Operating engineer should pay attention to the reasons for the crack of tungsten crucible bottom and find out the solution to solve those problems, so that the rate of finished tungsten crucible products can be improved. According to researchers, they show that reasons for the crack of tungsten crucible bottom mainly lie in the pressing step and sintering step.

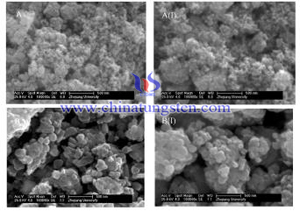

During the pressing process, if people select the thicker tungsten powder which would be difficult to suppress. It would result that the pressed compact higher needs a higher sintering temperature or more holding time in the next step sintering. What’s more, the thicker tungsten powder would waste much energy and time and has a great impact on the life time of the equipment. In the selection of the powder, in general, the thicker the tungsten powder is,the worse the compressibility is. And it would cause that users should choose a more large size of the mold cavity while filling it. A large powder needs for more pressure during the pressing. Except that, its compression is poor and it would directly reduce the density of the pressed compact. Therefore, when choosing the size of the powder, users should choose different sizes. The small size particles can fill the space leaving by large particles in the process of pressing to increase the density of compacts to avoid being cracked. In addition, the pressure of the pressing process also affects the qualified rate of the tungsten crucible compacts. Moreover, the qualified rate of the tungsten crucible compact is also affected by the hardness of the rubber sleeve, the greater the hardness, the more likely cause cracks.

During the sintering process, the selection of equipment and the sintering atmosphere has a greater impact on the qualified rate of the tungsten crucible. It’s required that tungsten crucible should be under a anaerobic condition, but there still exist oxygen on the surface of tungsten powder, the oxide film of its surface would hinder the sintering process. Oxygen of tungsten powder will be greatly removed in a hydrogen atmosphere which would increase the density of the product. In the selection of the sintering equipment, electric resistance furnace would be better than the induction furnace. The temperature of the upper and lower ends of the induction furnace is much lower than the middle part because of its structure, which would result in nonuniform sintering of tungsten crucible bottom.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Development of Tungsten Crucible in China

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:28

- Written by xuejiao

- Hits: 262

China is one of the richest tungsten resources storage countries in the world. Therefore, as deep processing product of tungsten, tungsten crucible industry has been continuously developed in China. The main applications of tungsten crucible in China are rare earth smelting, quartz glass, electronic spraying, crystal growth, etc.

Nowadays, our country has a production capacity for some conventional tungsten crucible, but there still exist some problems for the high-tech products. For example, the manufacturing technique for complex shape of the tungsten crucible is relatively rare, but such products play an important role in the area of high technology. And for instance, quartz glass has been widely applied in laser technology, astronomy and sophisticated technology. With the rapid development of modern technology, as the core components of quartz glass, tungsten crucible has a wide range prospects for development. The next few years, the development direction of the tungsten crucible will be large-size, high-quality, low-cost characteristics of tungsten crucible

With the rise of the tungsten industry in our country, the exploitation of tungsten resources has become a major problem. Our country has been exporting tungsten raw materials for a long time, which will affect the production of tungsten crucible. On the other hand, the utilization of the tungsten crucible is not enough. Tungsten Crucible has a long life time for using so that users can reuse it for many times. It can not only save costs but also protect the ecological environment. In addition, changing the export structure of the tungsten crucible which can save a lot of foreign exchange and improve our economy.

In recent years, the rapid development of chemical vapor deposition of can produce complex shape tungsten products in China. This is an important research direction of pure tungsten manufacturing technique. Such tungsten crucible that made by chemical vapor deposition process will be gradually on the market. Isostatic - sintering process in our country has reached the international advanced level and the scale of China's tungsten crucible development would be expanded with continuously improvement of the process. With the deepening of China's tungsten crucible research, international influence of domestic tungsten crucible is gradually rising, the tungsten crucible industry of China will occupy a major position in the international area in the future.

Prepare WO3 Plate SCR Denitration Catalyst--Dry Powder Mixing Method

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:23

- Written by chunyan

- Hits: 311

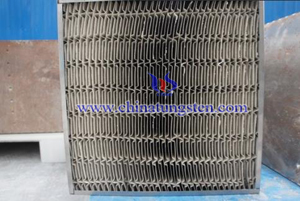

The main component of tungsten trioxide plate denitration catalyst is just similar to honeycomb denitration catalyst, both are based on vanadium pentoxide, tungsten trioxide as the main active substance, titanium dioxide as the carrier. Compared with cellular, it has a stronger capacity of ash anti-clogging, wear resistance, less consumption under dust and low pressure loss ect.; although its market share is only about 1/3 of the cellular, it will gradually expand with the further launch of high-dust flue gas denitration in China.

The main component of tungsten trioxide plate denitration catalyst is just similar to honeycomb denitration catalyst, both are based on vanadium pentoxide, tungsten trioxide as the main active substance, titanium dioxide as the carrier. Compared with cellular, it has a stronger capacity of ash anti-clogging, wear resistance, less consumption under dust and low pressure loss ect.; although its market share is only about 1/3 of the cellular, it will gradually expand with the further launch of high-dust flue gas denitration in China.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Applications of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:26

- Written by xuejiao

- Hits: 265

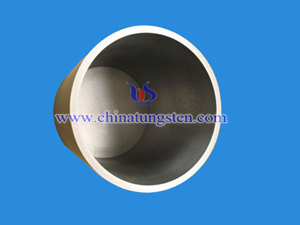

The main raw material of tungsten crucible is tungsten, and it is mainly formed through the deep processing of tungsten. Thanks to the high melting point and boiling point, a good thermal conductivity, low thermal expansion coefficient, a strong abrasion and corrosion resistance and other excellent properties of tungsten, tungsten crucible is widely applied in smelting of rare earth, quartz glass and crystal growth industries.

As an important member in the smelting of rare earth, functional performance and life time of tungsten crucible is very important. In the past, smelting of rare earth mainly use crucible which is welded by tungsten, molybdenum, or tantalum slab. But because there are many problems of this kind of crucible which would have seriously impact on their life time. The problems of welded crucible are more serious for high temperature or high purity rare earth metals. welding production out of the crucible short life is even more obvious. To solve this problem, the researchers developed a sintered tungsten crucible which can deal with the problem of crack of welding process. Sintered tungsten crucible has a high density, a high purity, long life time and other properties which make the rare earth smelting industry pay more attention to it. Compared with other types of crucibles, on the one hand, tungsten crucible would produce less pollution when smelting metal. On the other hand, its life time is longer, so the tungsten crucible is widely applied in rare earth industry.

Because of the melting point of tungsten can reach 3600℃, tungsten crucible can be considered as the cord cage and widely applied to the furnace of sapphire products. And the temperature tungsten crucible is generally above 2000 ℃ while working. Especially for sapphire products furnace, characteristics of a high purity, high density, crack-free, precise size, smooth inner and outer walls of the tungsten crucible can greatly improves the success rate of seed of the growth of sapphire crystal. In addition, tungsten crucible also plays a key role in controlling the quality of crystal pulling and the life time of sapphire products.

Quartz glass is an amorphous material which is only made of silica. The raw materials of it are crystal, silica and silicide, and quartz glass can be formed by high temperature melting or chemical vapor deposition. Therefore, it need for a high melting point and boiling point tungsten crucible as the core cage. In addition, the tungsten crucible can also greatly improve the rate of finished quartz glass.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

TiO2 Affects Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:21

- Written by chunyan

- Hits: 216

Nitrogen oxides is one of the main air pollutants, the large amount of NOx emitted into the air will not only cause a serious threat to the global environment, but also have an adverse effect on human health. The core of the current widespread use of SCR denitration technology is the catalyst, which the main active component is vanadium pentoxide; tungsten trioxide itself also has a denitration capability, besides it plays an important role in anti-toxic, anti-sintering, furthermore, it increases the ability of anti-oxidation of sulfur dioxide; titanium dioxide has a good sulfur resistance and stability, and join improving of the catalyst activity with the active ingredient.

Nitrogen oxides is one of the main air pollutants, the large amount of NOx emitted into the air will not only cause a serious threat to the global environment, but also have an adverse effect on human health. The core of the current widespread use of SCR denitration technology is the catalyst, which the main active component is vanadium pentoxide; tungsten trioxide itself also has a denitration capability, besides it plays an important role in anti-toxic, anti-sintering, furthermore, it increases the ability of anti-oxidation of sulfur dioxide; titanium dioxide has a good sulfur resistance and stability, and join improving of the catalyst activity with the active ingredient.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com