Tungsten Powder and Acoustic Sensor

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 17:42

- Written by xinyi

- Hits: 331

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

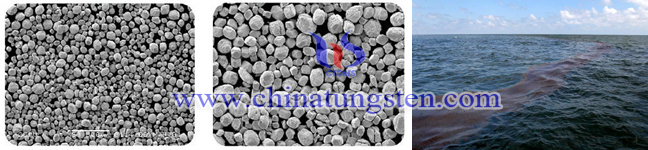

Tungsten Trioxide Photocatalyst for Ocean Oil Pollution Treatment

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 17:38

- Written by chunyan

- Hits: 243

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button Used for DTH Drill

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 15:38

- Written by xiaobin

- Hits: 268

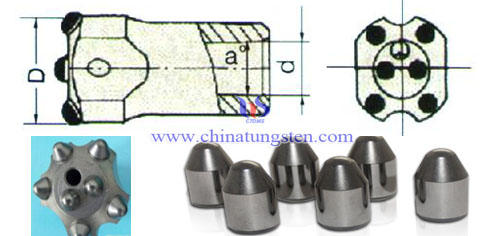

DTH drill uses compressed air as a power source to drive DTH hammer piston, and high frequency impact DTH drill by large impact energy. At the same time, the axial pressure and rotary torque effect from drilling bars rotate and break the rocks. The debris they produce high-pressure air is carried back to the earth surface. This kind of DTH drill has many advantages, such as high drilling efficiency, high quality of drilling, long service life of drill bits, not easily to be blocked and low cost, which as a kind of efficient drilling process and has been widely used in Mine blast, geological exploration, hydrology well drilling and other drilling purposes, especially effective in medium hard and hard formation. However, tungsten carbide buttons used for DTH drill directly affects DTH drill performance. Since in the process of drilling, the button under the action of high-speed impact of high frequency impact energy to hit the rocks, resulting in a larger volume breaking, DTH drill has higher efficiency. In addition, tungsten carbide buttons crush rock is a dynamic, non-linear failure process, which can be divided into 3 steps:

1. The moment of button and rock contacting, the load is small and rock has elastically deformed, and it appears a hemispherical elastic region under the button;

2. The buttons move down continuously, the load and the elastic region increases, the stress wave uses the point of button and rock contact as the center of the sphere, concentric spherical shape continuously to spread inside the rock. Meanwhile, it appears a high-stress area under the contact point of button and rocks. When the stress reached the limits of zone status, rocks were fractured;

3. The buttons intrude the rocks further, pressure on the surrounding rock to the side and gradually increased, eventually collapse from the surrounding rocks, forms a large volume of crushing, crushing cavity is formed.

In general, DTH drill uses 9 buttons, the bottom surface 3 by a clockwise spiral arrangement, other 6 edge evenly distributed. The bottom sets 3 buttons to ensure that each button can endure the largest impact energy, and the closest to the center uses inlay welding process, which is beneficial for coring. The other 6 edge buttons play a role in holding aperture and breaking the rocks surrounded.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Hob Description

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 15:39

- Written by xiaobin

- Hits: 305

Tungsten carbide hob is composed of the hard phase WC and the binder phase Co, its edges helically arranged along cylinder or cone to manufacture cutting tools, which has been widely used in cylindrical gears, worm and other toothed cylindrical workpieces fabricating. According to different applications, tungsten carbide hob can be specifically divided into gear hobs, worm hobs, fixed mounted hobs, non-involute hobs and so on. Compared with common high-speed steel hobs, tungsten carbide hobs have better performance in cutting rate and button efficiency. Solid tungsten carbide hob has been widely used in watches and some of the precision instrument manufacturing industry, such as processing a variety of small module gear; medium modulus solid carbide hob and panels have been used for machining cast iron and bakelite gear; modulus < 3 tungsten carbide hob is also used in steel gear manufacturing; in addition, tungsten carbide hob is also can be used for fabricating hardened wheel (HRC50-62).

Tungsten carbide worm hob is a kind of special tool for worm manufacturing. Its main transmission type and basic parameters of the worm (including module, pressure angle, helix angle, pitch diameter, number of thread, etc.) should work with the same worm. When the worm is large in outer diameter, shaft-mounted hob can be made; when the worm is small in outer diameter, the hob can be made integral with the mandrel shank-type structure. Tungsten carbide fixed mounted hob has different profiles, which only the last one button is the precise button. Gullet button and forming a workpiece identical to alveolar milling method of cutting a workpiece, the rest of the button are for rough cutting and the movements is as same as the gear hob. In addition, forming hob can effectively avoid the exhibition to the transition curve tooling generated the root, especially the ratchet hob. The mechanism of non-involute hob is similar to the gear hob, such as spline hob can be used for processing rectangular teeth, involute or triangular tooth spline shaft, which has better machining precision and efficiency than forming cutters. And it also can be used for arc gears, cycloid gears and sprockets manufacturing.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Cobalt Alloy Production Using Tungsten Powder Coating

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 18:25

- Written by Cristina

- Hits: 236

During production of tungsten cobalt alloy, to prevent sticking, aluminum oxide with ethanol is brushed to the boat. However, aluminum oxide will penetrate into alloy under high temperature will results in the uneven of bottom to enlarge the finish machining cost. At the same time, the service life of vacuum pump is shorter with absorption of aluminum oxide particle. This article introduces a tungsten cobalt alloy production using tungsten powder preparing method, it will realize the completely separation of tungsten cobalt alloy and graphite boat and will not affect quality of alloy.

Tungsten cobalt alloy production using tungsten powder coating manufacturing method:

A.Submicron tungsten powder preparation:

1.Disolve tungstic acid in distilled water, adding ammonium solution and heating, ammonium tungstate solution is obtained.

2. Quick freeze ammonium tungstate solution under 45~-50°C.

3. Transit ammonium tungstate into ultra freezing drying machine. After freezing out its appearance is like white cellular piece.

4. Smash the piece obtained from step 3.

5. Tungsten powder is obtained under 250~500°C by hydrogen reduction for 4~6 hours.

B. Preparing materials below:

PEG6000 10~20 parts.

Tween 80 5~10 parts.

Graphite glue 10~20 parts.

Anti-brasive carbon black 10~20 parts.

Submicron tungsten powder from step A 5~10 parts.

Water 30~50 parts.

C. Mixing tungsten powder and PEG6000.

D. Dissolve material in step C with distilled water.

E. Adding the rest material into solution of step D and stirring it evenly.

Advantages: This kind of tungsten cobalt alloy production using tungsten powder coating manufacturing method, use freezing tungsten powder to replace metal oxide powder, it has high purity, small grain size. Besides that, submicron tungsten powder produced by vacuum freezing drying method can absorbing other components when blended with coating due to its porosity inside.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com