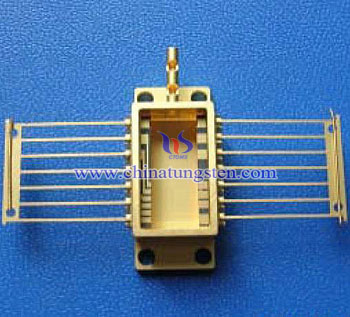

Tungsten Copper Heat Sink — Hot Forging

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 15:18

- Written by xiaobin

- Hits: 334

Tungsten copper heat sink materials not only have high density, high strength, high melting point and excellent wear and corrosion resistance, but also have high heat resistance and perfect thermal and electrical conductivity. It is important that it has matching thermal and linear coefficient of expansion to the chip and ceramic, which has a broad prospect in RF (Radio Frequency), microwave, optical communications and some other high-power electronic components. But the common tungsten copper heat sink materials fabricated by PM after Cu infiltrated will unavoidably appear some pores and defects, which has a bad effect on the hermeticity of electronics packaging materials. Hot forging is a kind new process that organically combines PM and hot hammering, it heated after sintered preform and forged in a closed die cavity. It can not only reduce the cutting loss effectively, but also can promote the densification and improve the structure and properties.

From the point of view microstructure, after forging high temperature tungsten copper composite material no larger diameter of the copper-rich region and Cu phase distributes uniformly. At the same time between the tungsten particles combine more closely, product density has been increased dramatically. In addition, after twice after forging, microstructure changes tungsten-copper composite material is not obvious at this time shows the deformation resistance and forging pressure inside the sample is quite internal sample no longer produce significant deformation and dislocation. After hot forging, tungsten copper material inside the pores decrease, increase density, air tightness and physical performance improved significantly. Through ultrasonic scanning analysis, we can find that the sample without forging has many small pores inside and there is almost no white dot after forging. On the other hand, processing tungsten-copper material through the internal temperature after forging without causing cracks larger pores gradually shrink or even disappear, thereby increasing the density of tungsten copper material, tungsten copper microstructure uniformity is further improved.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact Used for SF6 Circuit Breaker

- Details

- Category: Tungsten Information

- Published on Thursday, 07 July 2016 15:16

- Written by xiaobin

- Hits: 288

SF6 circuit breaker uses SF6 gas as dielectric medium. Compared with conventional air circuit breaker, it also belongs to air blast circuit breaker. But there are some differences, such as lower working pressure, in the process of blowing the arc, and gas is not discharged to the atmosphere, but in a closed loop system used. Due to the perfect insulation and interrupter properties of SF6 gas, SF6 circuit breaker has many advantages, such as good breaking ability, high voltage suitable for fracture, allow continuous breaking more frequently, small in noise, no security threat, small electro-mechanical wear and so on which is a king of “maintenance-free” circuit breaker with excellent performance and has been widely used in high-voltage circuit. As the voltage level of the SF6 circuit breakers imposed increasingly higher and higher, the requirements of physical and electrical performance is also increasing.

In general, SF6 circuit breakers should meet the design requirements that the hardness of contact > HRB 82, the density > 13g / cm3, the conductivity ≥ 50% IACS, and after a 20-time All-breaking capacity test, the contact surface burning amount should not exceed 3mm. Conventional ratio has two kinds of W-Cu40 and W-Cu 35, wherein the content of W should not be too high (≤70%), otherwise the burning rate will increase. First of all, choose fine W powder is beneficial for reducing the burning rate, but too fine W powder will make liquid copper difficult infiltrate and easily form crumb defects on the matrix. Adding sintering additives will remarkably decrease the electrical conductivity and the burning loss has an increasing trend on the surface of contacts after cut-off. In addition, the granularity composition also needs a proper mixing ratio; viewed from the manufacturing process, add proper amount of induced Cu powder when mixing; leave some place for re-press when compacting; the volume of liquid copper must be equal to tungsten skeleton pore volume during sintering infiltration and it should be surface cleaned after cooling.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Powder and Bronze Composite Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 July 2016 17:58

- Written by xinyi

- Hits: 337

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Product Catalogue

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 July 2016 19:37

- Written by yiping

- Hits: 281

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Deep Cryogenic Treatment Effect on Tungsten Carbide Materials

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 July 2016 15:51

- Written by xiaobin

- Hits: 304

First of all, viewed from micro structure, deep cryogenic treatment has no obvious effect on the WC granularity, contiguity, and γ phase mean free path of tungsten carbide materials. Carbide without cryogenic treatment contains only a small amount of brittle η phases, by comparison, after the cryogenic treatment due to carbide long-term exposure to extreme temperatures and η phase increases. There are some experiments found that after deep cryogenic treatment, tungsten carbide has more uniform distribution, the binder Co and hard phase WC combined firmer and the overall wear resistance is significantly improved. Furthermore, the deep cryogenic treatment temperature provides greater two-phase free energy difference (High-temperature phase α-Co (fcc structure) and Low temperature phase Σ-Co (hcp structure)). At such low temperature, the atomic diffusion capacity reduced and formed no-diffusion phase transition process. In the research of deep cryogenic treatment of TW carbide inserts, we can found that the blade without deep cryogenic treatment has both of Σ-Co phase andα-Co phase, while the blade after treatment only hasΣ-Co phase. It indicates that after deep cryogenic treatment, Co of TW has a complete martensitic transformation. Overall, deep cryogenic treatment can promote binder Co transfer fcc structure to hcp structure.

Due to the great difference of the coefficient of thermal expansion and linear expansion coefficient between WC and Co phases of tungsten carbide, tungsten carbide has large thermal stress inside after cooling. And WC phase is subjected to compression stress, Co phase is subjected to tensile stress. By cryogenic treatment can make the carbide obtained two-phase thermal stress relaxation, thereby increasing the strength of carbide cutting tools. In addition, in mechanical properties, carbide cutting tools after deep cryogenic treatment, the hardness has greatly improved (from HRA90 to improve HRA92, HV1764 increased to HV2263.7). While YG6X, YG8, YG10C, YT14 four grades after deep cryogenic treatment, Various grades of alloy coercive force has been significantly improved, significantly lower than the saturation magnetization, has improved hardness, density substantially constant and flexural strength dramatically.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com