Tungsten Carbide Forstner BitsⅠ

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 November 2015 14:43

Forstner bits are named for Benjamin Forstner, a 19th century American gunsmith who is credited with inventing them. Gunsmiths were the first to popularize the bit; they prized it for its ability to bore a smooth-sided hole in woodwork.

Tungsten carbide Forstner bits are a cylindrical drill bit used to bore precisely flat, deep holes into wood. It is particularly popular in furniture making and other large-scale woodworking projects in part because of its ability to drill deeply and precisely, even against the grain or through various inlays and joined pieces. They can cut on the edge of a block of wood, and can cut overlapping holes. Because of the flat bottom to the hole, they are useful for drilling through veneer already glued to add an inlay. They require great force to push them into the material, so are normally used in drill presses or lathes rather than in portable drills. Unlike most other types of drill bits, they are not practical to use as hand tools.

Forstner bits typically come in a range of different diameters, they are commonly available in sizes from 8–50 mm (0.3–2.0 in) diameter. Sawtooth bits are available up to 100 mm (4 in) diameter.

(To be continued. This article is divided into several parts. Here is part 1. For part 2 please refer to http://news.chinatungsten.com/en/tungsten-information/80701-ti-10455)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅻ

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 November 2015 14:39

In last part we get conclusions that the wear progress of tungsten carbide tool with (Al,Cr)N coating film is slower than the (Ti,Al)N coated one for the former one has higher hardness and higher oxidation temperature. And this part we go on to other conclusions based on the above experiments and analysis.

3) In addition, because the cutting temperature becomes lower due to the lower coefficient of friction of the (Al,Cr)N coating film, the wear progress of the (Al,Cr)N coated cemented tungsten carbide tool became slower.

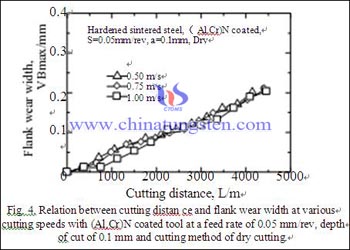

4) In cutting hardened sintered steel with a (Al,Cr)N coated cemented tungsten carbide tool, there was little influence of the cutting speed on the tool wear within the range of the cutting speed from 0.50 m/s to 1.00 m/s.

As mentioned above, it was clear that the (Al,Cr)N coated cemented tungsten carbide tool is an effective tool material in cutting hardened sintered steel.

(The end-This article is divided into several parts. Here is part 12. For part 11 please refer to http://news.chinatungsten.com/en/tungsten-information/80698-ti-10452)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅺ

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 November 2015 14:37

In last part we know that the tool wear mechanism and cutting temperature of tungsten carbide tools in the cutting speed range from 0.50 m/s to 1.00 m/s are similar. And this part we come to get a final conclusion based on the above experiments and analysis.

4. Conclusion

In this study, to clarify the effectiveness of aluminum-chromium coating film for cutting hardened sintered steels, tool wear was experimentally investigated. The hardened sintered steel was turned with an aluminum-chromium based coated tungsten carbide tool according to a physical vapor deposition (PVD) method. Moreover, the tool wear of the aluminum-chromium based coated item was compared with that of the (Ti,Al)N coated tools.

(To be continued. This article is divided into several parts. Here is part 11. For part 10 please refer to http://news.chinatungsten.com/en/tungsten-information/80697-ti-10451; for part 12, please refer to http://news.chinatungsten.com/en/tungsten-information/80699-ti-10453)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅹ

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 November 2015 14:32

In last part we know that The flank wear progress of tungsten carbide tool with (Al,Cr)N coating changes little with cutting speed from 0.5 m/s to 1.0 m/s. And this part we explain further the similarity of tool wear mechanism between the cutting speed of 0.50 m/s and 1.00m/s.

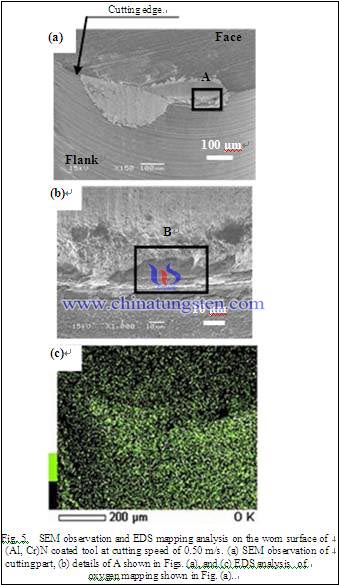

Fig. 5 shows the tool wear in the case of a cutting speed of 0.50 m/s. Fig. 5 (a) and (b) shows the SEM observation and Fig. 5 (c) shows the EDS analysis. Fig. 5 (b) shows the details of A shown in Fig. 5 (a). Fig. 5 (c) shows the EDS analysis in the case of the oxygen (O) mapping on the cutting part shownin Fig. 5 (a).

First, as compared with the wear of the tungsten carbide tool in the cutting speed 1.00 m/s shown in Fig. 1 (b) and that of the cutting speed 0.50 m/s shown in Fig. 5 (a), the tool wear of the cutting speed 0.50 m/s shows the same characteristics as that of the cutting speed 1.00 m/s. Next, as compared with the worn surface of the cutting speed 1.00 m/s indicated by “B” shown in Fig. 3 (ii)(a) and that of the cutting speed of 0.50 m/s indicated by “B” shown in Fig.5 (b), many striae scratched by any hard material are remarkably found on the worn surface in the case of both the cutting speed 1.00 m/s and the 0.50 m/s. Therefore, the main tool wear mechanism of the cutting speed 1.00 m/s and the 0.50 m/s is considered to be abrasive wear.

Finally, as compared with the oxygen element on the worn surface of the cutting speed 1.00 m/s shown in Fig. 3 (ii)(b) and that of the 0.50 m/s shown in Fig. 5 (c), the oxygen mapping on the cutting part shown in the cutting speed 0.50 m/s shows the same characteristics as that of the cutting speed 1.00 m/s. Therefore, the cutting speed is considered to have little influence on the cutting temperature within the range of the cutting speed from 0.50 m/s to 1.00 m/s.As mentioned above the cutting speed is considered to have little influence on the tool wear within the range of the cutting speed from 0.50 m/s to 1.00 m/s.

(To be continued. This article is divided into several parts. Here is part 10. For part 9 please refer to http://news.chinatungsten.com/en/tungsten-information/80632-ti-10439; for part 11, please refer to http://news.chinatungsten.com/en/tungsten-information/80698-ti-10452)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Process for the Manufacture of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 November 2015 09:07

Ammonium tungstate, ammonium paratungstate, ammonium metatungstate or hydrated tungsten trioxide is produced by passing tungstate anions through an anion exchange membrane into an aqueous solution containing ammonium cations under the driving force of an electrical potential for a time sufficient to achieve a pH within the range in which the desired tungsten compound will form.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Metallo-Organic Deposition of Tungsten Oxide Films from Alkylammonium Tungstate Solutions

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 November 2015 08:55

Metallo-organic deposition of tungsten oxide films from alkylammonium tungstate solutions

This paper describes a simple and inexpensive metallo-organic deposition (MOD) process for forming electrochromic tungsten oxide (WO3) films on glass. The thin films of WO3 were made by air firing (500–700°C) films from xylene/2-propanol solutions of bis-(di-n-octylammonium) tetratungstate, [(n-C8H17)2NH2]2[W4O13]. The process coats glass with undoped films ranging in colour from faint yellow to dark brown, and can be used to make gradients of these colours. The colour is determined by the firing parameters and results from residual carbon and tungsten suboxides in the film due to incomplete firing. Increased firing temperatures or longer firing times removes the carbon and produces films with higher crystallinity. Electrochemical doping with acid (H+) switches the colour gradient films to a uniformly blue colour.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sintering Process Effect on Tungsten Copper Electrode Properties IV

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 17:06

When the temperature rises from 1150 ℃ to 1250 ℃, tungsten skeleton density from the 12.15g / cm3 increased to 12.39g / cm3. However, after that sintering temperature continues to rise, in the third stage and post-sintered tungsten skeleton, the density change is small. At this moment, the majority of the pores are completely separated, closed cell number is greatly increased, and pore shape tends to be spherical and shrinking, is not conducive to the process of post-infiltration.

From the aspects of sintering kinetics, the sintered tungsten copper alloy electrodes tungsten powder mainly diffusion and flow of two different mechanisms. Especially in the media and high temperature sintering, surface diffusion becomes very obvious. At this time due to the fine-grained powder, which powder is larger than the surface area of the active surface of the large number of atoms, the diffusion surface it is relatively easy to carry out, which also makes sintered tungsten skeleton easily enter the third stage from the second stage.

More information about sintering process effect on tungsten copper electrode properties, click here:

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sintering Process Effect on Tungsten Copper Electrode Properties III

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 17:04

Tungsten powder unit-based sintering can be divided into three sections, which include coupling phase, sintered neck formation, closed pores spheroidization and reducing phase. In order to obtain the desired tungsten skeleton, we should try to control the sintering process within the second section, which is beneficial for porosity reducing and ensuring the best powder sintering temperature of different granularity.

As the temperature increases, the density of tungsten copper electrodes increase in the first two stages of sintering. Initial contact point or contact surface of tungsten powder changes into crystalline combination, through nucleation, growth and other atomic processes to form a sintered neck, then to a large number of atoms migrate bonding surface tungsten particles makes the sintering neck to expand, narrow particle spacing and form continuous pore network, and because of grain growth, grain boundary migration began, the area swept by grain boundary pores will miss, thereby forming tungsten skeleton connection.

More information about sintering process effect on tungsten copper electrode properties, click here:

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅸ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:53

In last part we know that the (Al,Cr)N coating has lower oxidation temperature and a lower coefficient of friction, which also explains less wear for (Al,Cr)N coated tungsten carbide tool. And this part we make experiments to test the influence of cutting speed on tool wear.

As mentioned above, (Al,Cr)N was found to have superior properties for coating material compared to (Ti,Al)N in cutting hardened sintered steel.

In cutting hardened sintered steel at various cutting speeds, the wear progress of tungsten carbide tool was investigated at a feed rate of 0.05 mm/rev and a depth of cut of 0.1 mm. Fig. 4 shows the influence of the cutting speed on the tool wear. There is little influence of the cutting speed on the tool wear within the range of cutting speed from 0.5 m/s to 1.0 m/s. So, SEM observation and EDS analysis was carried out on the worn surface.

(To be continued. This article is divided into several parts. Here is part 9. For part 8 please refer to http://news.chinatungsten.com/en/tungsten-information/80629-ti-10438)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅷ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:52

In last part we know that the (Al,Cr)N coating is harder than the (Ti,Al)N one and make the coated surface of tungsten carbide tool more resistant to abrasive wear which is the main wear mechanism in our experiments. And this part we will explain the second reason of why the wear progress is slower for (Al,Cr)N coated tungsten carbide tool.

Second, as compared with the oxygen element on the worn surface of the (Ti,Al)N coating film shown in Fig. 3 i(b) and that of the (Al,Cr)N coating film shown in Fig. 3 ii(b), the oxygen element of the (Al,Cr)N coating film, which was turned at long cutting distance, is less than that of the (Ti,Al)N coating film. Therefore, the cutting temperature of the (Al,Cr)N coating film is considered to be lower than that of the (Ti,Al)N coating film, and the wear progress of the (Al,Cr)N is slower than that of the (Ti,Al)N. One reason for the lower cutting temperature of the (Al,Cr)N coating film is as follows.

That is, the (Al,Cr)N coating film has a lower coefficient of friction as compared with the (Ti,Al)N coating film. Furthermore, the (Al,Cr)N coating film has a higher oxidation temperature as shown in Table III. This is considered to be the reason why there is less tool wear of the (Al,Cr)N coated tungsten carbide tool.

(To be continued. This article is divided into several parts. Here is part 8 For part 7 please refer to http://news.chinatungsten.com/en/tungsten-information/80628-ti-10437; for part 9 please refer to http://news.chinatungsten.com/en/tungsten-information/80632-ti-10439)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com