Japan Will Remove the Fukushima Nuclear Fuel Frit

- Details

- Category: Tungsten's News

- Published on Thursday, 21 September 2017 22:55

- Written by meiwei

- Hits: 662

(Xinhua News Agency, July 26) According to Japanese media reports, the crew used the robot to investigate the 3 unit of the Fukushima Daiichi nuclear power plant in Tokyo electric power company as of July 22nd.

Read more: Japan Will Remove the Fukushima Nuclear Fuel Frit

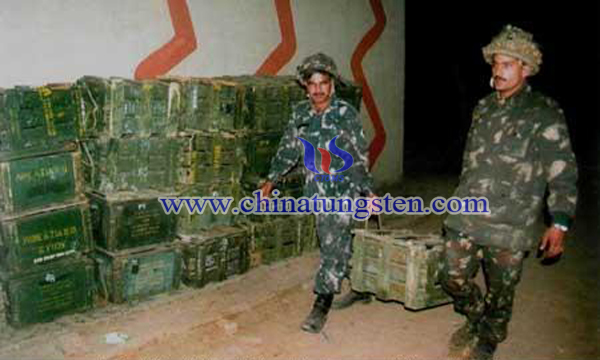

With the Low Quality, Indian Army Ammunition Difficult to Support Ten Days

- Details

- Category: Tungsten's News

- Published on Thursday, 21 September 2017 21:40

- Written by meiwei

- Hits: 655

July 24 British "Jane's Defense Weekly" website reported that, compared to the Chinese army land, sea and air armed forces of various types of rocket missiles, all types of ammunition include tungsten alloy, high explosive shells, and other special tungsten alloy ammunition are strong independent production, yield and varieties are available.

Read more: With the Low Quality, Indian Army Ammunition Difficult to Support Ten Days

Praseodymium Oxide Price - Sep. 20, 2017

- Details

- Category: Tungsten's News

- Published on Wednesday, 20 September 2017 14:01

- Written by Shuxia

- Hits: 602

Rare earth price in China continues to adjust slightly amid the price of praseodymium oxide and neodymia declines. Downstream purchasers have adequate stocks of NdFeB.

Tungsten Market Sees Price Consolidation

- Details

- Category: Tungsten's News

- Published on Wednesday, 20 September 2017 14:07

- Written by Shuxia

- Hits: 776

Analysis of latest tungsten market in China from Chinatungsten Online: “Confidence is worth more than gold” is applicable to the tungsten market, particularly when there is no hedging in the market. In the long-term, supply and demand determine tungsten price, confidence in the short-term. When tungsten price rises, market confidence will grow, which boosts price at high speed. On the contrary, prices will decline when customers are depressed.

Ammonium Tetramolybdate Price - Sep. 20, 2017

- Details

- Category: Tungsten's News

- Published on Wednesday, 20 September 2017 13:56

- Written by Shuxia

- Hits: 700

Molybdenum market in China remains steady as there are no favorable factors in the fundamentals. The latest price of molybdenum concentrate, ferromolybdenum and ammonium tetramolybdate is unchanged from the previous trading day.

sales@chinatungsten.com

sales@chinatungsten.com