[Know Tungsten] Wolframite Slime Recycle – Oil Agglomeration Method

- Details

- Category: Tungsten Audio

- Published on Friday, 29 September 2017 15:29

- Hits: 428

Wolframite slime is a difficult issue of tungsten beneficiation due to its fine particle, recycle for fine minerals particle in slime is even more difficult. In recent years, to deal with fine wolframite slime more efficient, there are methods for gathering first and beneficiation second. Oil agglomeration method is a newly developed wolframite slime recycle process.

[Know Tungsten] Wolframite Slime Recycle – Maudsley Tabling Gravity Separation Method

- Details

- Category: Tungsten Audio

- Published on Thursday, 28 September 2017 15:25

- Hits: 423

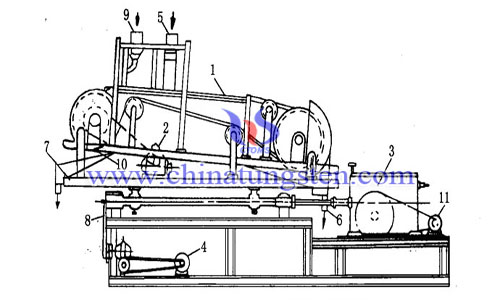

Wolframite slime is a beneficiation problem due to its fine grain size. In China, use flotation method to deal with wolframite slime is common method. At abroad, Maudsley tabling gravity separation method is used to realize wolframite slime recycle.

[Know Tungsten] Wolframite Slime Recycle – High Intensity Magnetic Flotation Method

- Details

- Category: Tungsten Audio

- Published on Wednesday, 27 September 2017 16:51

- Hits: 459

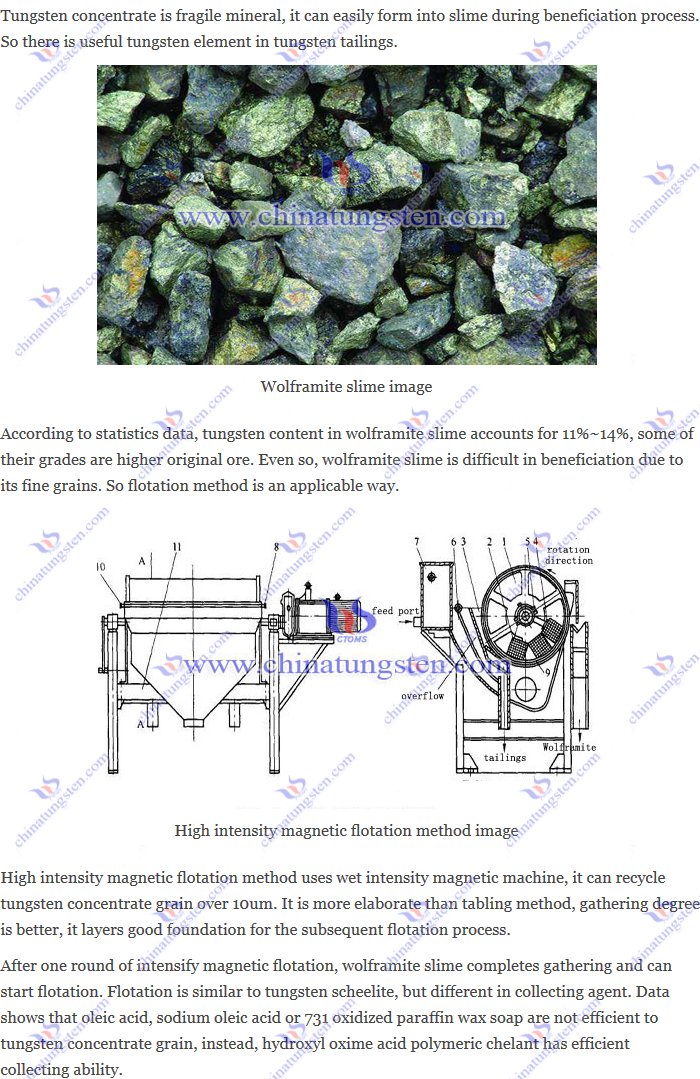

Tungsten concentrate is fragile mineral, it can easily form into slime during beneficiation process. So there is useful tungsten element in tungsten tailings.

Thor Mining Completes Drilling at the Pilot Mountain Tungsten Project in Nevada

- Details

- Category: Tungsten Audio

- Published on Tuesday, 26 September 2017 11:38

- Hits: 472

The AIM-listed firm said a potential second lode has been identified 20 metres to the north of the existing Desert Scheelite lode, while a 28 metre wide zone of copper, zinc and tungsten mineralisation was intersected near the surface at the Good Hope prospect.

Heavy Metal on a Tungsten Basis with High Radiation Absorption Capacity Offers an Alternative to Lead

- Details

- Category: Tungsten Audio

- Published on Tuesday, 26 September 2017 11:31

- Hits: 404

EU Directive 2011/65/EU (RoHS 2) regulates the use of certain hazardous substances in electrical and electronic equipment. Lead, which is often used as radiation shielding or for anti-scatter grids, is ranked at the top of the list, even higher than mercury and cadmium.

Chinese Curbs Send Tungsten Price Soaring

- Details

- Category: Tungsten Audio

- Published on Tuesday, 26 September 2017 11:18

- Hits: 427

The price of one of the most critical materials for the Western world's economy and defenses is spiking faster than any other major commodity.

China Sends Tungsten Price, One of the West’s Most Critical Materials Soaring

- Details

- Category: Tungsten Audio

- Published on Tuesday, 26 September 2017 11:04

- Hits: 380

The price of one of the most critical materials for the Western world’s economy and defenses is spiking faster than any major commodity.

[Know Tungsten] Tungsten Concentrate Coarse Separation – Photoelectric Separation

- Details

- Category: Tungsten Audio

- Published on Monday, 11 September 2017 18:28

- Hits: 442

Tungsten concentrate coarse separation is gathering tungsten ore from mine, then enters the first premium grade separation process before gravity separation. Due to uneven distribution of tungsten concentrate in quartz vein mines, tailings mixed in the gathering process is huge. Separate tungsten concentrate and tailings at primary stage can promote efficiency of subsequent processes, save cost, time and lower wastage.

[Know Tungsten] Eddy-flow Micro-Bubble Flotation Column

- Details

- Category: Tungsten Audio

- Published on Tuesday, 29 August 2017 08:45

- Hits: 531

Flotation column is a new type of tungsten scheelite flotation equipment, it has a simple structure, small footprint, low cost, high degree of automation, low infrastructure investment, good flotation index and many other advantages, and gradually become mainstream in tungsten ore flotation.

[Know Tungsten]Backflow Non-filling Type Flotation Column

- Details

- Category: Tungsten Audio

- Published on Monday, 28 August 2017 08:43

- Hits: 473

Flotation column is a new type of tungsten scheelite flotation equipment, it has a simple structure, small footprint, low cost, high degree of automation, low infrastructure investment, good flotation index and many other advantages, and gradually become mainstream in tungsten ore flotation.

sales@chinatungsten.com

sales@chinatungsten.com