Ammonium Metatungstate Preparing Solid Superacid

- Details

- Category: Ammonium Metatungstate

- Published on Tuesday, 15 November 2016 11:10

- Written by chunyan

- Hits: 1644

According to the classical definition, a superacid is an acid with an acidity greater than that of 100% pure sulfuric acid, which has a Hammett acidity function (H0) of −12. According to the modern definition, superacid is a medium in which the chemical potential of the proton is higher than in pure sulfuric acid. The known superacid can be divided into liquid and solid superacid according to the appearance. In petrochemistry, superacidic media are used as catalysts, especially for alkylations. Typical catalysts are sulfated oxides of titanium and zirconium or specially treated alumina or zeolites. The solid acids are used for alkylating benzene with ethylene and propylene as well as difficult acylations, e.g. of chlorobenzene.

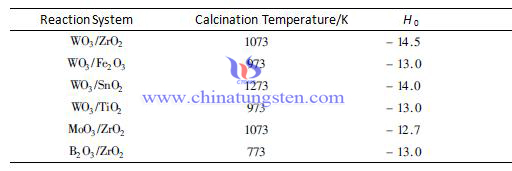

In 1998, the presence of supported oxide solid superacid has immediately caused a wave of research in the field of catalyst, which has been reported to have three types, namely WO3, MoO3 and B2O3 oxides, with the acidity showing as the following table:

The supported oxide solid superacid (WO3/ ZrO2) which Arata firstly studied has the acidity lower than that of SO42- / MxOy-type solid superacid (SO42- / ZrO2) with H0 < -16.0 (while the H0 of WO3/ ZrO2 is lower than 14.5), but its stability in solution and reducing atmosphere and heat is better than that of SO42- / ZrO2 solid superacid; moreover, it is selectivity for some specific reactions, such as isomerization of high-carbon alkanes, is higher than that of SO42- / MxOy catalyst.

The results showed that ammonium metatungstate (AMT) can be used as a tungsten source for the preparation of supported oxide solid superacid (WO3/ ZrO2), with the preparation methods of coprecipitation and sol-gel method; both of the two methods are also called as one-step method since it is introducing WO3 at the same time of preparation process, the processes are:

1. Coprecipitation method: Pour the ZrOCl2 solution into a mixed solution of ammonium metatungstate and ammonia water to conduct coprecipitation, and adjust the final pH value to 9.0, then carry out filtering, washing, drying and calcination to get the final product.

2. Sol-gel method: Add the zirconium n-propoxide into the mixed solution of ethanol and nitric acid containing with ammonium metatungstate to get gelling; remove the ethanol by carbon dioxide supercritical drying method after the obtained gel is aged for 2 hours; and then dry it in vacuum for 3 hours respectively at temperature of 383 K and 523 K, and finally carry out calcination at high temperature.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com